Applications of Carbide

Tungsten carbide is primarily used as cutting tools (turning tools, milling cutters, planing tools, drills, boring tools, saw blades, etc.), mold materials (drawing dies, powder metallurgy molds, stamping dies, wire […]

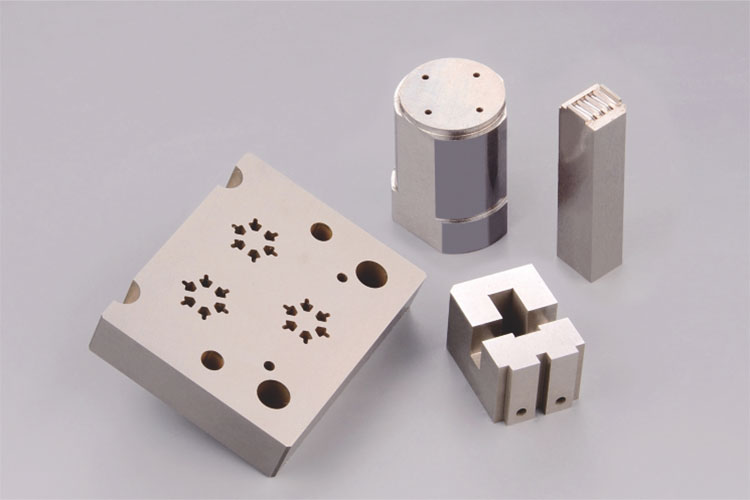

Tungsten carbide is primarily used as cutting tools (turning tools, milling cutters, planing tools, drills, boring tools, saw blades, etc.), mold materials (drawing dies, powder metallurgy molds, stamping dies, wire drawing dies, etc.), mining and geological drilling tools, and wear-resistant parts. Carbide materials, known for their exceptional hardness and durability, are extensively utilized across various sectors of the manufacturing industry. Below, we delve into the primary uses of carbide and how they contribute to efficiency and precision in industrial operations.

1. Cutting Tool Materials

Carbide is predominantly used in the production of cutting tools due to its ability to maintain sharpness and resist wear under extreme conditions. These tools include:

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

- Turning Tools and Milling Cutters: Ideal for shaping and cutting operations on numerous materials.

- Drills and Planing Tools: Employed for creating holes and shaping materials with precision.

- Specialty Cutting Applications: Tungsten-cobalt carbide variants are particularly effective for machining short chips from materials such as cast iron, brass, and engineered woods. Conversely, tungsten-titanium-cobalt carbide excel in processing long chips from various steels, enhancing their suitability for tasks ranging from fine to rough machining.

The selection of carbide type (e.g., higher cobalt content for rough machining due to increased toughness) is crucial based on the specific machining requirements and the nature of the material being processed.

2. Mold Materials

Carbide’s robustness makes it an excellent choice for mold-making applications, particularly in cold working environments. Key uses include:

- Deep Drawing Dies: Tungsten-cobalt carbide grades like K10 and K20 are optimal for small to medium dies, whereas K40 is preferred for larger dies and more strenuous applications such as blanking.

- Cold Extrusion and Heading Dies: These applications benefit from carbide’s strength and wear resistance, ensuring long-lasting performance under repetitive stress.

3. Measuring Instruments and Wear-Resistant Parts

The precision and longevity required in measuring tools and wear-resistant components make carbide an ideal material choice:

- Measuring Instruments: Tools such as micrometers, gauge blocks, and plug gauges often incorporate carbide in their design to enhance wear resistance, thereby extending their usable life and maintaining measurement accuracy.

- Wear-Resistant Components: Parts like precision rolling rolls, lathe tips, and bearings in precision grinding machines utilize carbide to withstand wear and deformation. This is crucial in maintaining the high precision required in specialized machining operations.

Conclusion

The diverse applications of carbide underscore its pivotal role in modern manufacturing and engineering. From enhancing the durability of cutting tools to extending the lifespan of molds and precision instruments, carbide continues to be a material of choice for applications demanding the highest levels of durability and precision. Whether you are involved in tool manufacturing, mold design, or the production of specialized components, integrating carbide can significantly elevate the quality and efficiency of your operations.