What is the manufacturing for carbide nozzle process?

Cheap factory. The manufacturing carbide nozzle process of tungsten steel involves several stages, including material selection, sintering, cutting, CNC, WEDM, EDM, grinding, and surface treatment.

The manufacturing process of tungsten carbide nozzles consists of several steps, including material selection, sintering (required for special dimensions), cutting the shape (using fast wire cutting for the blank), punch press, CNC, WEDM, EDM, internal and external cylindrical grinding, tungsten carbide surface grinding, hydraulic presses, and more. Depending on the different shapes and requirements of the tungsten carbide nozzles, various process combinations are selected, typically requiring professional engineers to arrange the processes. The general machining steps can refer to case studies, with three different tungsten carbide nozzle machining examples. Below is an overview of the process.

1. Material Selection

- Composition: The process begins with the selection of high-quality tungsten carbide, a compound of tungsten and carbon. Often, tungsten carbide for nozzles is mixed with cobalt or nickel, which acts as a binder and enhances the material’s mechanical properties. The typical composition ranges from 6% to 30% of these binder metals.

- Quality Assurance: The raw materials are rigorously tested to ensure purity and consistency, crucial for the final properties of the nozzles.

2. Sintering

- Cutting: First, use a fast wire EDM machine to process rods or plates, cutting the tungsten carbide blocks to an appropriate size.

- Sintering: Large-sized tungsten carbide nozzles utilize the sintering process when suitable-sized tungsten carbide rods or sheets are not available. Tungsten carbide parts are generally sintered, a form of heat treatment that involves heating the compacted carbide powders to a temperature below the melting point. Sintering enhances their strength and hardness by bonding the metal grains.

- Controlled Environments: The heat treatment process is carefully controlled to avoid any deformities and to achieve the desired mechanical properties such as hardness and toughness.

3. Cutting and Shaping

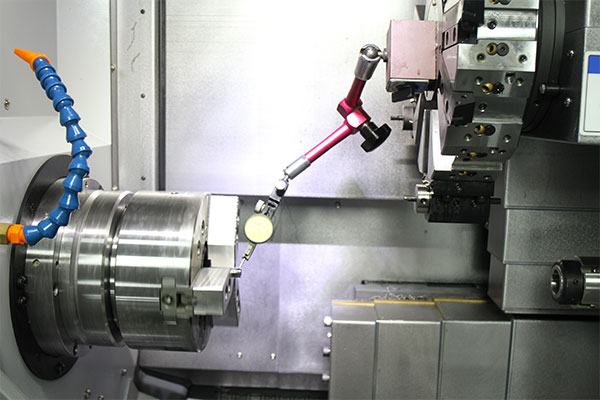

- Precision Machining: Utilizing advanced CNC machinery, the tungsten carbide blanks are cut and shaped according to precise specifications. Techniques such as turning, milling, drilling, grinding, WEDM, and sometimes EDM (Electrical Discharge Machining) are employed.

- Dimensional Accuracy: This stage is critical for ensuring that the nozzles meet the exact dimensions required for specific applications, which is essential for the functionality of the nozzles in their final use.

4. Surface Treatment

- Finishing Techniques: After sintering, the nozzles undergo various surface treatments to improve their wear and corrosion resistance. This can include CVD (Chemical Vapor Deposition), PVD (Physical Vapor Deposition), and other coatings that enhance performance.

- Polishing and Grinding: The nozzles are also polished and ground to achieve a smooth surface, which is crucial for minimizing friction and wear in practical applications.

5. Quality Control and Testing

- Inspection: Each nozzle is inspected for dimensional accuracy, surface quality, and overall performance. Advanced measuring and testing equipment are used to ensure each piece meets the stringent standards required.

- Performance Testing: Functional tests, including flow tests and stress tests, are conducted to ensure the nozzles perform well under the expected operating conditions.

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

Conclusion

The manufacturing process of tungsten carbide nozzles is complex and requires high levels of expertise in metallurgy and precision engineering. Each stage of the process plays a crucial role in determining the quality and performance of the final product. These nozzles are essential in applications where high wear resistance, durability, and precise performance are required, making their meticulous production process well worth the effort.