Carbide parts hole with Precision Polishing to Ra0.015

Cheap processing factory. Carbide, as a material used in mold or mechanical parts, has been widely applied due to its wear resistance and high-temperature performance. However, in many cases,

Tungsten carbide, used as a material for dies or mechanical parts, has excellent wear resistance and high-temperature resistance. In many cases, the parts or holes used require a mirror-like surface finish. At Get Mold Company, we specialize in delivering carbide parts polishing with a precision of Ra0.015, ensuring top-tier quality and performance.

Understanding Carbide and Its Polishing Needs

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

Carbide’s impressive hardness, typically between 85HRA to 95HRA, makes it a challenging material to work with, particularly during the finishing stages. The machining process often creates burrs that can affect the functionality and aesthetic of the part. Removing these burrs, or polishing, is therefore a critical step in the production of carbide parts.

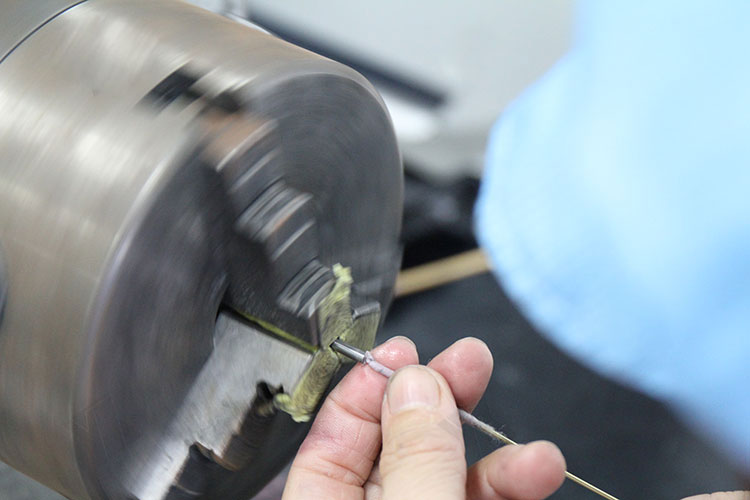

Techniques for Achieving Ra0.015 Smoothness

Different smoothing techniques are employed based on the required finish:

- For basic smoothing needs, oilstones are utilized to grind away imperfections.

- Higher precision requirements, such as those needed for carbide parts demanding a smoothness of Ra0.015, necessitate the use of diamond paste for polishing. This method ensures an ultra-fine finish, crucial for high-performance parts.

The Importance of Expert Polishing Techniques

Handling the polishing of tungsten carbide parts, including intricate hole polishing, requires not only the right materials but also skilled technicians. Our team at Get Mold Company comprises experienced professionals adept in managing the delicate balance of achieving desired smoothness without compromising the part’s dimensional tolerances.

Quality Control in Carbide Part Polishing

To maintain our commitment to quality, our machining personnel conduct regular inspections throughout the polishing process. This rigorous quality control ensures that every part meets both our standards and customer expectations.

Why Choose Get Mold Company?

Get Mold Company continues to lead in technological advancements and technique refinement. Our commitment to quality and precision in carbide part polishing is unmatched in the industry. Whether your project requires high-precision hole polishing or surface finishing, we guarantee excellence and reliability.

For more information on our carbide polishing services or to discuss your specific needs, please feel free to contact us. Let us help you achieve the perfect finish for your carbide components, enhancing both their function and longevity.