Carbide Tip Die Drills Wholesale Customization

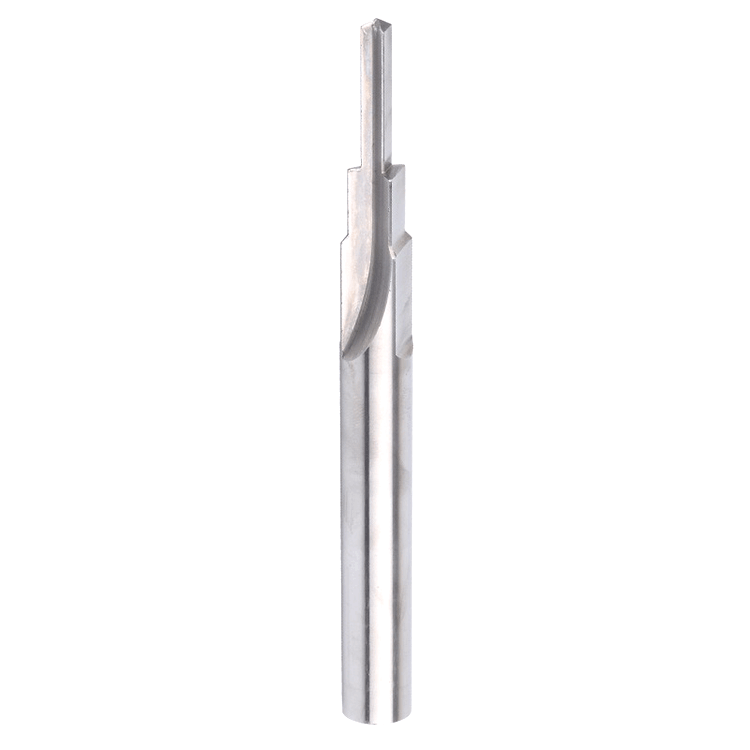

In the field of modern precision machining, choosing the right tool is crucial for processing quality and efficiency. The carbide tip die drill, as a high-performance cutting tool, has become […]

In the field of modern precision machining, choosing the right tool is crucial for processing quality and efficiency. The carbide tip die drill, as a high-performance cutting tool, has become one of the preferred tools in the machining industry due to its excellent performance and wide applicability.

Product Features

Material Advantage

Made from high-quality tungsten carbide, it offers ultra-high hardness and wear resistance. The carbide material ensures the tool maintains stable processing accuracy during high-speed cutting, significantly extending its service life.

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

Customization Flexibility

We offer comprehensive customization services, including options for hole shape, blade diameter, and precision. It can perfectly meet different processing needs, whether it’s conventional machining or special process requirements.

Versatile Specifications

- Effective processing depth: options include 4mm, 15mm, 25mm

- Length of drill blade: 6mm, 15mm, 30mm available

- Options for handle length: 40mm, 60mm, 150mm

- Handle diameter specifications: 2mm, 4mm, 9mm

Professional Design

External cooling design is adopted for effective temperature control during cutting, enhancing processing efficiency. The hydraulic clamping connection ensures stability and precision of tool installation.

Application Benefits

- High Precision Machining: Special tool geometry ensures extremely high machining accuracy.

- Long Service Life: Quality carbide material offers excellent wear resistance.

- Strong Adaptability: Capable of various types of precision hole processing, with wide applicability.

- Superior Efficiency: Rational cutting parameter design improves processing efficiency.

Usage Recommendations

- Strictly follow the recommended cutting parameters.

- Regularly check tool wear conditions.

- Ensure sufficient supply of coolant.

- Pay attention to the compatibility between the workpiece material and the tool.

With its excellent performance and flexible specification options, this carbide tip die drill can meet a variety of needs in the field of modern precision machining. It is the ideal choice for improving machining efficiency and quality.