Classification of carbide

Carbides can be divided into two categories: cermet carbides and steel-bonded carbides. Cemented carbide materials for cutting tools are classified into six categories: P grade (steel), M grade (mixed), K […]

Carbides can be divided into two categories: cermet carbides and steel-bonded carbides. Cemented carbide materials for cutting tools are classified into six categories: P grade (steel), M grade (mixed), K grade (cast iron), N grade (non-ferrous metals), S grade (heat-resistant alloys), and H grade (hard materials).

Main Categories of Carbide

- Metal Ceramic Carbide

- Composition: These are composed of refractory metal carbide powders like tungsten carbide (WC) and titanium carbide (TiC), bonded with metals such as cobalt, molybdenum, or nickel.

- Manufacturing: The process involves pressing the mixture into a desired shape and then sintering it at high temperatures.

- Applications: Due to their exceptional hardness and wear resistance, metal ceramic carbides are predominantly used in making cutting tools for machining metals and other materials.

- Steel-Bonded Carbide

- Composition: This type blends one or several types of carbides with carbon steel or alloy steel powders, creating a material that bridges the properties of high-speed steels and metal ceramic carbides.

- Characteristics: After sintering, these materials can be annealed, machined, quenched, and tempered, resulting in high hardness and wear resistance. They can also be forged and welded, and exhibit good heat, corrosion, and oxidation resistance.

- Versatility: Steel-bonded carbides are suitable for applications requiring both the toughness of steel and the hardness of carbide, such as in certain tooling and wear applications.

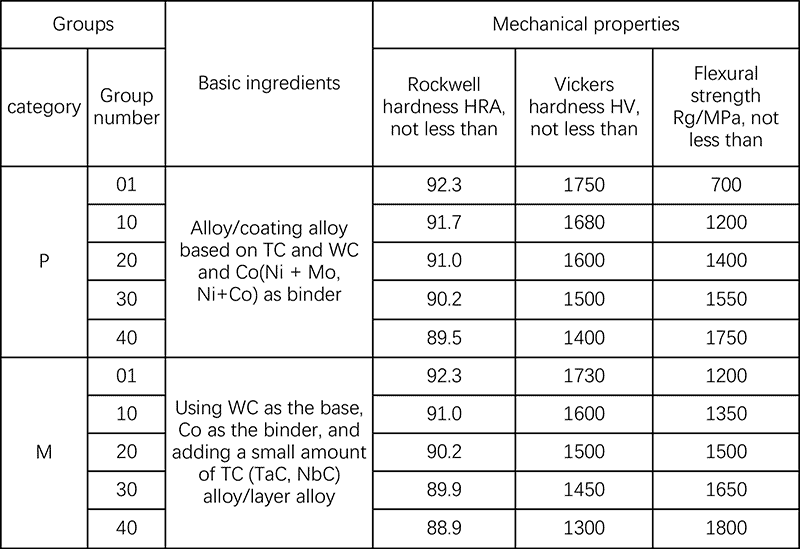

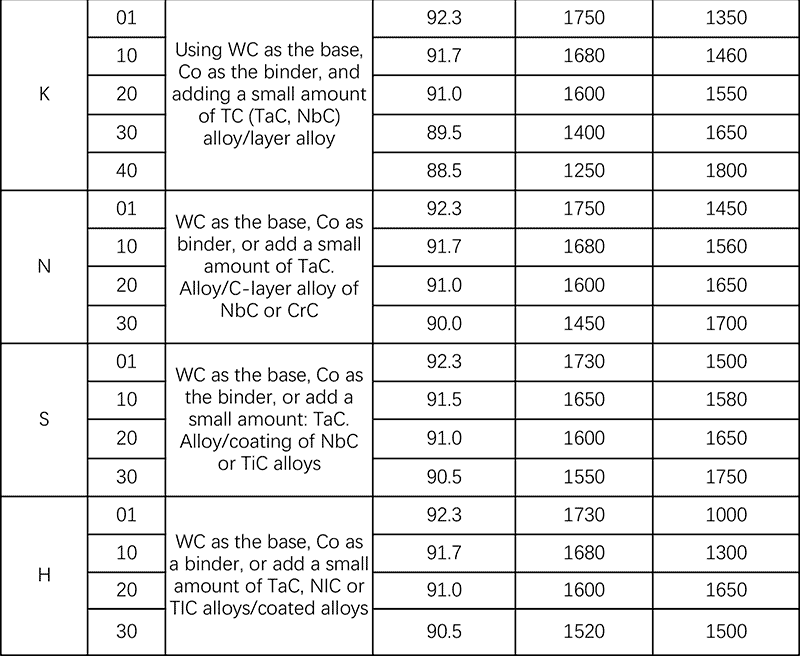

Basic composition and mechanical properties of commonly used carbide

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

Classification for Cutting Tool Carbide

Carbide materials for cutting tools are classified into six distinct categories based on the application environment and desired properties:

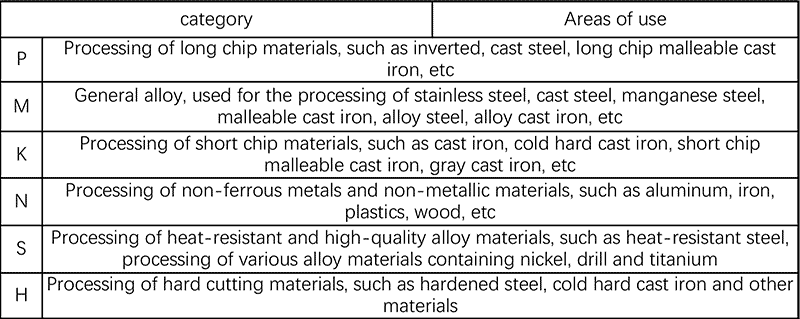

- P Grade (Steel): Optimized for cutting steel, these carbides resist plastic deformation and withstand moderate to high speeds.

- M Grade (Mixed): Suitable for cutting stainless steel and high-temperature alloys, offering a balance between hardness and toughness.

- K Grade (Cast Iron): Best for cast iron and non-ferrous metals, focusing on wear resistance and thermal shock resistance.

- N Grade (Non-ferrous): Ideal for aluminum and other non-ferrous materials, designed to prevent built-up edge.

- S Grade (Heat-resistant Alloys): Used for machining materials such as titanium and nickel-based alloys, capable of withstanding high temperatures.

- H Grade (Hard Materials): Appropriate for hard materials that require a very hard cutting material, such as hardened steels and hard cast irons.

Each category further subdivides into specific groups (e.g., P01, P10, P20) to fine-tune properties like wear resistance and toughness to match more precisely the demands of specific machining tasks.

Categories and application fields of carbide

Conclusion

Selecting the correct type of carbide is essential for achieving optimal performance in manufacturing and tooling applications. Whether your needs involve intricate cutting tasks or robust wear-resistant components, understanding these classifications helps in choosing the most suitable carbide type for your specific requirements.

Contact Us for Expert Carbide Solutions

As a leading manufacturer specializing in carbide machining, we offer precision services including grinding, EDM, wire EDM, CNC machining, and polishing. Our expertise ensures high-quality products tailored to meet the unique challenges of your projects. Feel free to reach out with any inquiries or for more detailed information on how we can assist with your carbide needs.