Principles, Characteristics, and Applications of Electron Beam Machining Technology

Introduction Electron Beam Machining (EBM) is an emerging special machining technology that has seen significant development in recent years. It is primarily used for drilling, welding, surface treatment, additive manufacturing, […]

Introduction

Electron Beam Machining (EBM) is an emerging special machining technology that has seen significant development in recent years. It is primarily used for drilling, welding, surface treatment, additive manufacturing, lithography, precision machining such as cutting and slotting, and can achieve high-precision machining. Electron beam machining technology utilizes the power of a focused high-energy electron beam under vacuum conditions for precision machining of various materials. This technology falls under the category of micro fine high-energy beam machining, which also includes laser beams, plasma, and ion beams. These beams are capable of inducing heating, melting, vaporization, and other physical phenomena to achieve ultra-fine levels of material removal, joining, growth, and modification.

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

Principles of Electron Beam Machining

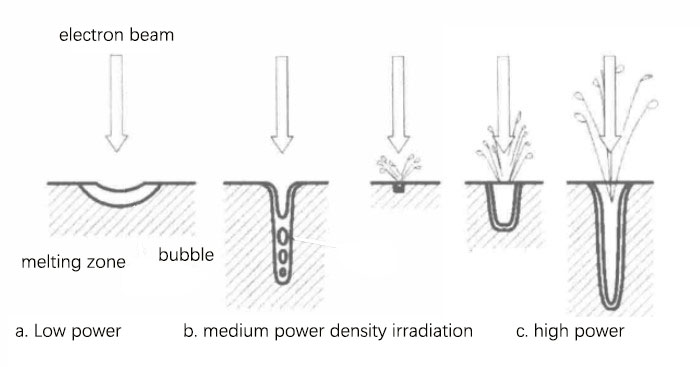

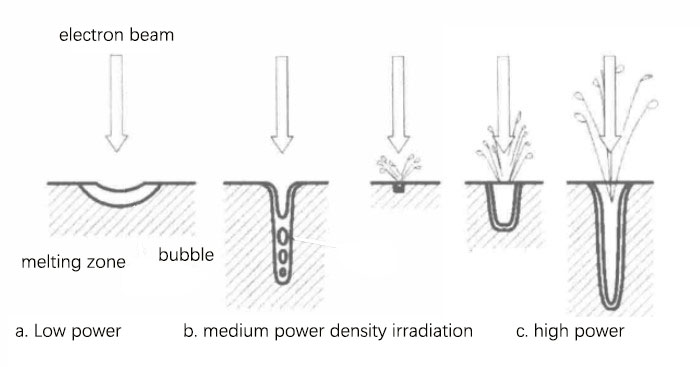

Electron beam machining involves emitting a beam of electrons from a heated cathode in a vacuum. The electrons are accelerated towards an anode through an accelerating electrode and focused using electromagnetic lenses. This process concentrates high energy into small spots ranging from 0.1 to 10 μm in diameter, achieving energy densities between 10^6 to 10^9 W/cm². The high-speed electrons impact the workpiece surface, converting their kinetic energy into thermal energy, which causes rapid heating, melting, and vaporization of the material.

1.1 Principle of electron beam machining.

Characteristics of Electron Beam Machining

- High Precision and Control:

Electron beams can be focused to extremely fine diameters, as small as 0.01 μm, allowing for microfine machining and deep hole drilling with high aspect ratios. - High Energy Density:

The focused beam can achieve very high energy densities sufficient to melt and vaporize virtually any material, regardless of its melting point. - Efficient Machining:

Due to the high energy density and efficient energy utilization, machining times are typically short, even for materials up to 5 mm thick. - Versatile Material Machining:

Electron beam machining is suitable for a wide range of materials, including hard, brittle, ductile metals, non-metallic materials, and heat-sensitive substances. - Minimal Deformation:

As a non-contact machining method, electron beam machining does not exert significant mechanical stress on the workpiece, minimizing deformation. - Automation Capability:

Electron beams can be precisely controlled in terms of intensity, diameter, and positioning, facilitating automation and complex geometric machining.

Applications of Electron Beam Machining

1.2 Machining using electron beams.

- Electron Beam Welding:

Used for precision welding of various metals and alloys in the automotive, aerospace, and electronics industries. - Electron Beam Drilling:

Ideal for creating precise holes in hard materials for applications like fuel injection nozzles and cooling holes in turbine blades. - Surface Treatment:

Improves surface properties such as hardness, wear resistance, and corrosion resistance in tools and dies. - Additive Manufacturing (EBAM):

Electron beams melt and solidify metal powders layer by layer to create complex structures in aerospace and medical applications. - Lithography:

Electron beam lithography is crucial in semiconductor manufacturing, creating detailed patterns on substrates. - Precision Machining:

Used for cutting, grooving, and shaping materials in microelectronics and micro-optics industries.

Advantages

- Electron beam machining achieves nanometer-level accuracy, making it ideal for fabricating intricate structures.

- The focused nature of the beam minimizes thermal diffusion, reducing the heat-affected zone and potential material damage.

- It can machine a broad range of materials under controlled conditions, ensuring high purity and quality of the machined surfaces.

Limitations

- The complexity and cost of the required equipment may limit accessibility, particularly for small-scale operations.

- Safety concerns must be managed due to the high-energy nature of the beam.

- The depth of machining can be limited, restricting its use to certain applications or material thicknesses.

Conclusion

Electron beam machining technology offers a powerful solution for microscale and nanoscale manufacturing challenges across various industries. With its ability to provide precise, efficient, and versatile material machining, it continues to be a critical tool in the advancement of modern manufacturing and engineering.