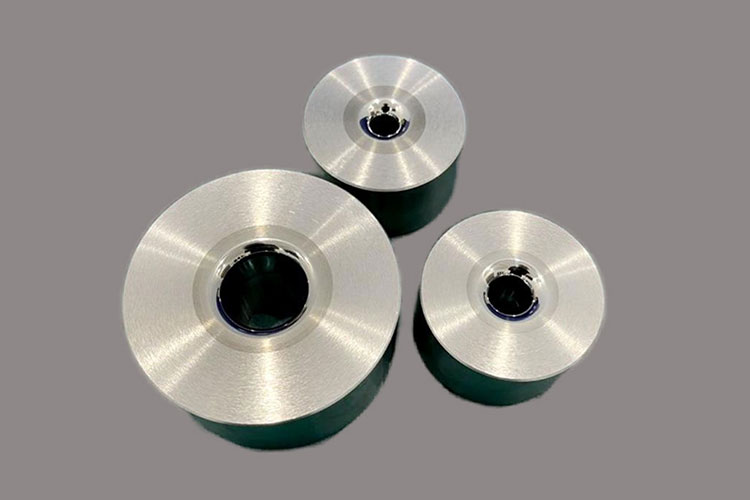

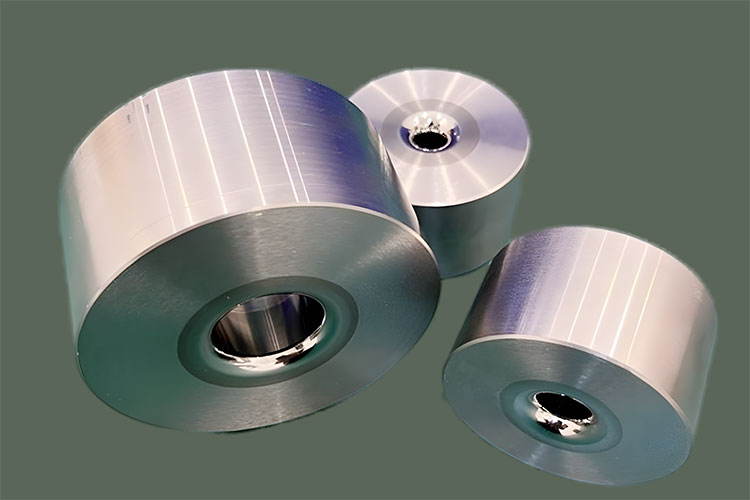

Manufacturing of flat head tungsten carbide die

Flat head screws are common mechanical fasteners, and the precision and quality of their die manufacturing directly affect the product’s performance. This article will elaborate on the key points in […]

Flat head screws are common mechanical fasteners, and the precision and quality of their die manufacturing directly affect the product’s performance. This article will elaborate on the key points in the manufacturing process of flat head screw carbide dies.

I. Die Structure Features

- Head Forming Area

- Flatness control precision ≤ 0.01mm

- Fillet transition design R0.2-0.3mm

- Ensures uniform stress to prevent stress concentration

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: lei.jiang@carbide-products.com,

II. Material Selection and Requirements

- Carbide Selection

- Uses ultrafine grain carbide

- Strict control of the Tungsten-Cobalt ratio

- Hardness requirement HRA90-92

- Performance Index

- Compressive strength ≥ 3500MPa

- Bending strength ≥ 2200MPa

- Abrasion resistance is 5-8 times better than ordinary high-speed steel

III. Precision Machining

- Grinding Process

- Uses diamond wheel for precision grinding

- Gradually decrease the machining allowance in steps

- Surface roughness Ra ≤ 0.2μm

- Special Treatment

- Optional plasma nitriding

- PVD coating treatment

- Enhances surface hardness and wear resistance

IV. Quality Control System

- Dimension Detection

- Utilizes a three-coordinate measuring system

- Assists detection with laser scanning technology

- Establishes a complete inspection record

- Performance Testing

- Hardness Distribution Test

- Abrasion Resistance Assessment

- Life Span Verification

V. Application Optimization Suggestions

- Environmental Adaptation

- Selects the material suitable for different application scenarios

- Considers the working temperature range

- Assesses corrosion resistance needs

- Productivity Enhancement

- Optimizes the design of die structure

- Increases die change efficiency

- Prolongs the lifespan of the dies

By strictly following the above manufacturing process and quality control requirements, the high quality and stability of flat head screw dies can be ensured. High-quality dies not only improve the production efficiency of nails but also ensure the consistency and reliability of the product, meeting the application needs of different industries. In actual production, the process parameters should be continuously optimized and improved according to specific usage requirements.