The influence of WC grain size and Co content on the hardness and toughness of tungsten carbide

Tungsten carbide (WC) is a composite material comprising tungsten carbide particles and a metal binder, typically cobalt (Co). The properties of tungsten carbide, such as hardness, toughness, and wear resistance, […]

Tungsten carbide (WC) is a composite material comprising tungsten carbide particles and a metal binder, typically cobalt (Co). The properties of tungsten carbide, such as hardness, toughness, and wear resistance, are significantly influenced by two primary factors: the grain size of the tungsten carbide and the content of cobalt in the composite.

Tungsten carbide has different applications depending on the WC grain size and cobalt content. Fine and ultra-fine grains are used for cemented carbide products requiring high precision and excellent surface finish, such as carbide cutting tools for precision machining and mold components. Medium and coarse grains are more suitable for rough machining and heavy-duty cutting tools. High cobalt content is applied in mining tools and certain wear parts, while low cobalt content is used for cutting tools and wear-resistant coatings. For wear-resistant parts that require abrasion resistance, compressive strength, and surface finish, fine and ultra-fine WC raw materials are utilized. The specific requirements for tungsten carbide grain size vary according to the specific application of the carbide.

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

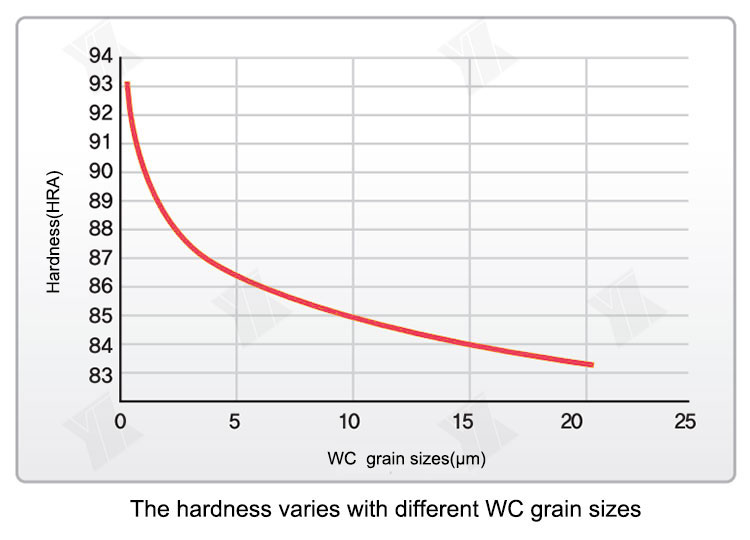

The hardness varies with different WC grain sizes.

Influence of WC Grain Size on Hardness and Toughness

- Hardness:

- Smaller Grain Size: Smaller WC grains typically result in higher hardness. This is because finer grains offer less space between them, reducing the impact of the binder and increasing the density of the carbide phase.

- Larger Grain Size: Conversely, larger grains can decrease the overall hardness because of the increased presence and effect of the binder, which is generally softer than the carbide.

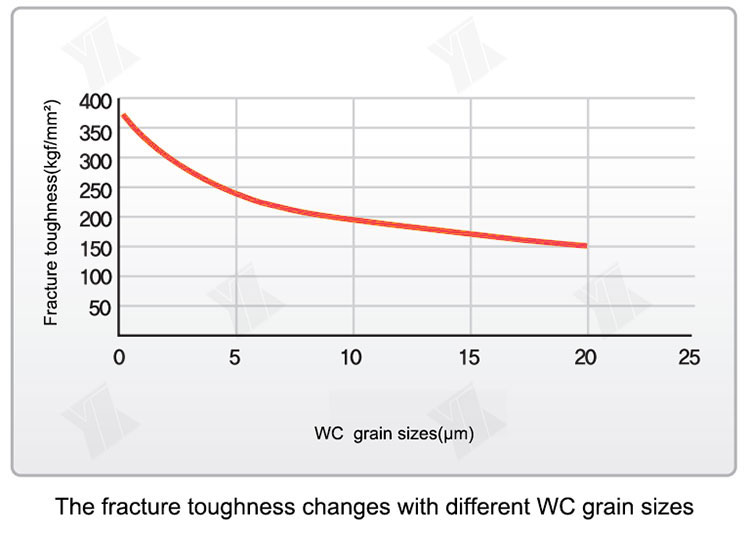

- Toughness:

- Smaller Grain Size: While smaller grains increase hardness, they can sometimes reduce toughness because the material becomes more brittle.

- Larger Grain Size: Larger grains enhance the toughness of the material due to the increased ductility provided by the binder. This makes the carbide more capable of absorbing impacts without fracturing.

The fracture toughness changes with different WC grain sizes.

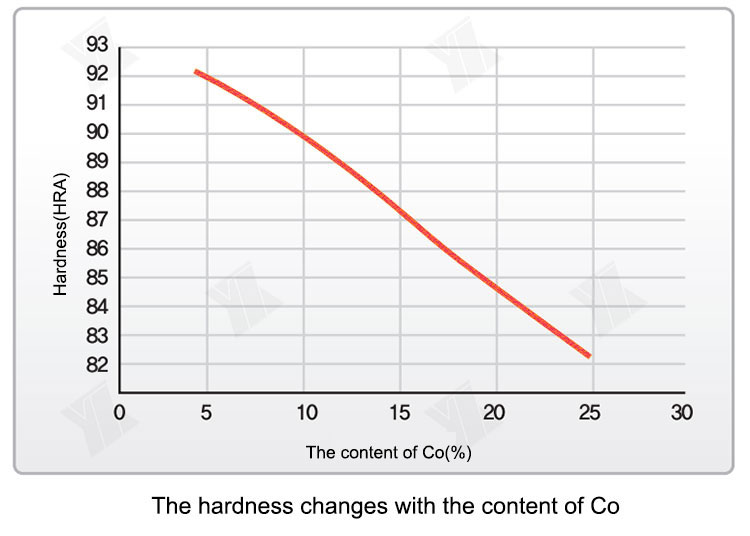

The hardness changes with the content of Co.

Influence of Cobalt Content on Hardness and Toughness

-

- Hardness:

- Higher Cobalt Content: Increasing the cobalt content generally results in a decrease in hardness. Cobalt acts as a binder and is softer than tungsten carbide. More cobalt creates a matrix that is less rigid.

- Lower Cobalt Content: Lower amounts of cobalt increase the proportion of tungsten carbide, which is harder, thus enhancing the overall hardness of the material.

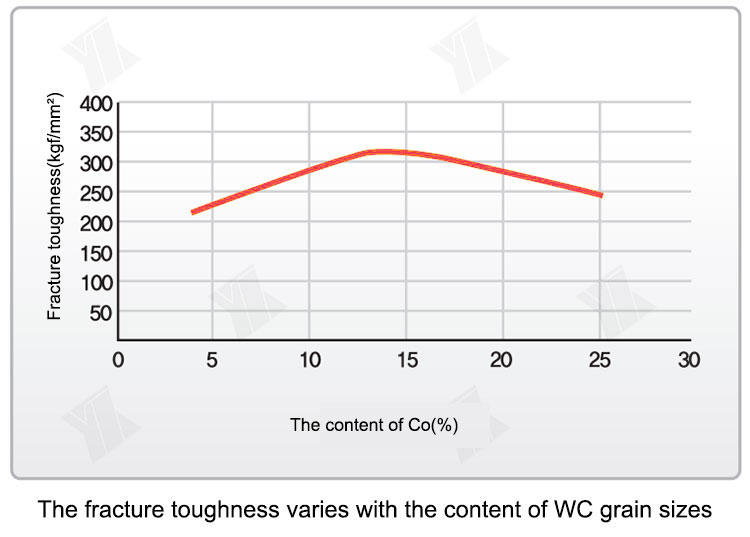

- Toughness:

- Higher Cobalt Content: More cobalt improves the toughness of tungsten carbide. The metal binder’s ductility helps to absorb and distribute stresses more evenly throughout the material, reducing the likelihood of crack propagation and failure.

- Lower Cobalt Content: Less cobalt makes the material harder but can compromise its toughness, making it more susceptible to brittle fracture under impact or stress.

- Hardness:

The fracture toughness varies with the content of WC grain sizes.

Applications Based on Grain Size and Cobalt Content

- Fine and Ultra-fine Grains: Used in applications requiring high precision and excellent surface finishes, such as in machining of metals where detail and finish are critical.

- Medium and Coarse Grains: Better suited for rough machining and heavy-duty cutting tools where toughness is more critical than fine detail.

- High Cobalt Content: Ideal for applications where impact resistance is crucial, such as in mining tools and certain wear parts.

- Low Cobalt Content: Used in applications where hardness and wear resistance are paramount, such as in cutting tools and wear-resistant coatings.

Conclusion

The choice of tungsten carbide material depends heavily on the specific requirements of the application. Manufacturers and engineers must consider the desired balance between hardness and toughness, which is influenced by the WC grain size and the cobalt content. By adjusting these parameters, tungsten carbide can be tailored to meet the demands of various applications, ranging from precision cutting instruments to robust mining equipment. Get Technology Co., Ltd., with its expertise in processing tungsten carbide parts, utilizes these principles to deliver parts that meet stringent tolerance and performance standards.