How to Dress Diamond & Carbide Grinding Wheels | Expert Guide

Guide to dressing grinding wheels. Learn proper techniques for carbide, diamond, and CBN wheels. Improve cutting performance and wheel longevity.

Dressing a carbide grinding wheel is essential for maintaining its effectiveness and prolonging its life. Superabrasive wheels, such as those made from diamond or CBN (Cubic Boron Nitride), require specific techniques due to their exceptional hardness. Here’s a comprehensive guide on how to dress these types of wheels, along with the importance and different methods of doing so.

I. Overview of Dressing Techniques for Superabrasive Grinding Wheels

Superabrasive wheels necessitate specialized dressing methods beyond conventional techniques:

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

-

Diamond Pen Dressing

- Utilizes a single-point diamond dresser or a multi-point diamond blade.

- This technique requires careful handling to maintain the sharpness of the wheel. After dressing, the wheel should be sharpened further to enhance its cutting edge.

- The diamond pen is set to contact below the wheel axis at a slow, consistent feed rate to ensure even dressing.

-

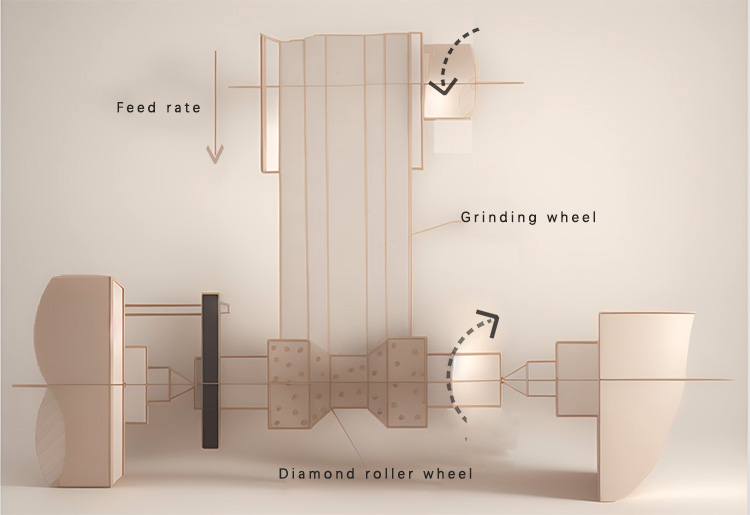

Roller Dressing

- Employs a roller that moves in a rolling motion relative to the wheel.

- This method fractures the bond bridges within the wheel, creating micro-edges on the abrasive grains.

- While it offers lower efficiency and precision, it is effective for producing sharper grains and is suited for specific applications.

-

Grinding Wheel Dressing

- Uses ordinary abrasive wheels or diamond rollers to dress CBN wheels.

- Allows for dressing across the wheel’s full width, providing a short dressing time and low force.

- This method is capable of replicating complex wheel profiles and is effective for general-purpose dressing.

II. The Importance and Methods of Wheel Dressing

-

Purpose and Importance

- Dressing restores the wheel’s original grinding performance and geometry, which involves sharpening the abrasive edges and clearing material from the wheel’s surface.

- Proper dressing reduces grinding force and prevents the burning of the workpiece.

-

Preparation Before Dressing

- Ensure the main spindle bearings are at a stable temperature to avoid geometric inaccuracies and abnormal wear.

- Handle diamond dressing tools with care due to their fragility.

-

Use and Maintenance of Dressing Tools

- Regular maintenance of the dressing tools is crucial as a dull tool degrades the wheel’s performance.

- Rotate the diamond tool regularly to maintain its sharpness.

-

Selection of Dressing Methods

- The choice of dressing method depends on the specific requirements of the application and the type of grinding wheel used.

- Factors to consider include the hardness of the wheel, the precision required, and the specific characteristics of the workpiece material.

Conclusion

Dressing techniques for carbide grinding wheels are vital for achieving optimal grinding results and extending the life of the wheel. By choosing the appropriate dressing method and maintaining proper care of the tools, operators can ensure efficient and precise grinding operations.

Interactive Segment: Do you have experience with Superabrasive grinding wheels? Which dressing technique do you prefer? Share your experiences and tips in the comments below to help others improve their grinding processes.