Introduction to grinding wheel in grinding processing

Using the appropriate grinding wheel on a grinding machine can improve the machining precision of the workpiece. Grinding can process various metals such as copper, aluminum, stainless steel, structural steel, […]

Using the appropriate grinding wheel on a grinding machine can improve the machining precision of the workpiece. Grinding can process various metals such as copper, aluminum, stainless steel, structural steel, high-hardness quenched steel, mold steel, and tungsten carbide, nickel alloys, titanium alloys, etc. For different materials, selecting different grinding wheels can enhance processing efficiency and quality.

Common types of grinding machines include cylindrical grinding machines, internal grinding machines, surface grinding machines, and centerless grinding machines. Grinding machines are characterized by high spindle speed, hydraulic transmission system, ensuring smooth transmission and high precision.

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: lei.jiang@carbide-products.com,

Grinding processes on a grinding machine can encompass cylindrical surfaces (internal and external), stepped end faces, flat surfaces, as well as grinding of threads, gear profiles, splines, and keyways.

The grinding wheel is the cutting tool used in grinding operations. It consists of numerous small abrasive grains bonded together by a binder. The characteristics of the grinding wheel depend on the properties and composition ratios of the abrasive and binder.

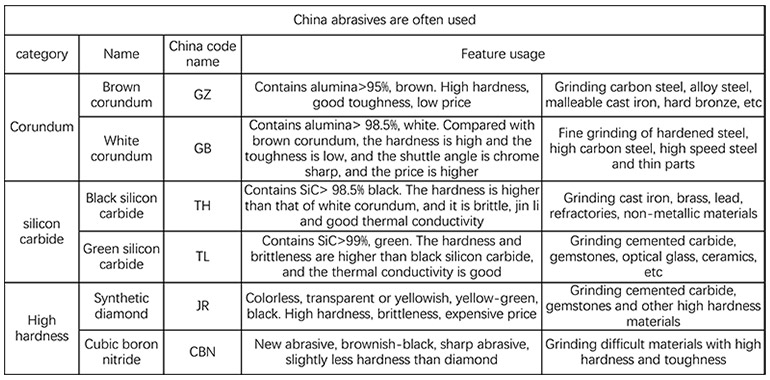

- Abrasive: The abrasive is the main raw material of the grinding wheel. It has sharp edges, high hardness, heat resistance, and a certain degree of toughness. Common abrasives are listed in the table below.

- Grit size: Grit size refers to the size of the abrasive particles. The particle size is indicated by a grit number, where a larger number represents a smaller particle size. Micro grit indicates finer particle sizes and is represented by the letter “W.” A smaller micro grit number indicates a finer particle size.

- Binder: The strength, impact resistance, heat resistance, and corrosion resistance of the grinding wheel depend primarily on the properties of the binder.

- Hardness: The hardness of the grinding wheel refers to the ease with which abrasive grains on the surface of the wheel dislodge under external forces. If the abrasive grains are easily dislodged, the wheel has low hardness, while a wheel with high hardness retains the abrasive grains more firmly.

- Structure: The structure of the grinding wheel refers to the tightness or looseness of its composition.

Get Mold is a professional manufacturer of precision grinding machines, providing various processing services for high-speed steel, tungsten carbide, and ceramics. We have processing equipment such as cylindrical grinding machines, internal grinding machines, surface grinding machines, centerless grinding machines, and optical profile grinding machines. Feel free to inquire for more information.