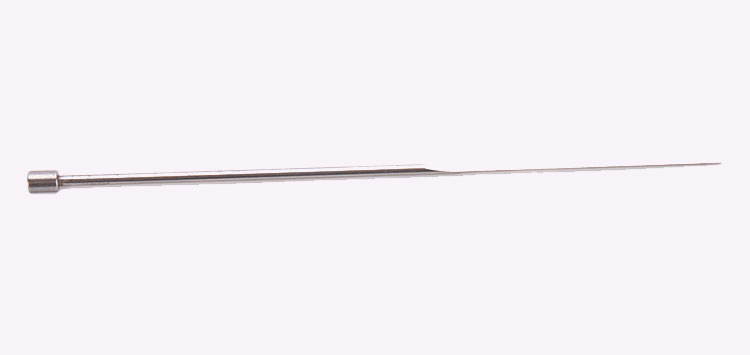

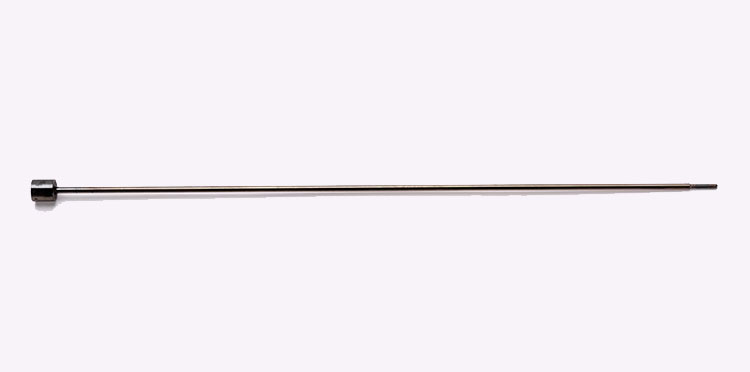

Machining of tungsten carbide needles with a diameter of 0.02mm

Cheap factory. Our company specializes in machining ultra-fine mold punches with a minimum diameter of 0.02mm by grinding tungsten carbide rods to a diameter of 0.02mm.

Our company specializes in machining ultra-fine mold punches with a minimum diameter of 0.02mm by grinding tungsten carbide rods to a diameter of 0.02mm. Tungsten carbide punches are essential components in metal stamping dies, and high-precision products demand even higher requirements for mold punches.

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

Tungsten carbide is characterized by high hardness, with a range of 85 to 95 HRA, equivalent to 68 HRC to 81 HRC. It has properties such as high wear resistance and corrosion resistance, making it an excellent material for punch production. These characteristics make it an ideal material for manufacturing punches that require longevity and the ability to withstand harsh conditions, ensuring a long service life.

We can tailor the processing of raw materials based on customer requirements and provide material certifications.

The grinding angle of our tungsten carbide punches ranges from 10° to 90°. Grinding can be done on one end or both ends, with a cylindrical shape. The tip can be processed to a flatness of 0.02mm, chamfered, or formed into various shapes. They can be used for metal stamping dies or other high-precision components. The end of the punch can be ground into a pointed shape.

Heat treatment of the surface is possible.

Quality Control and Customization

Inspection and Testing: Each batch of tungsten carbide punches undergoes strict dimensional verification and appearance inspection to ensure they meet the precise specifications and high standards expected by the customer.