How to select materials for blanking dies?

The selection of blanking dies materials is influenced by several factors, including the physical properties of the blanking material such as hardness, expected die life, production volume, and product requirements […]

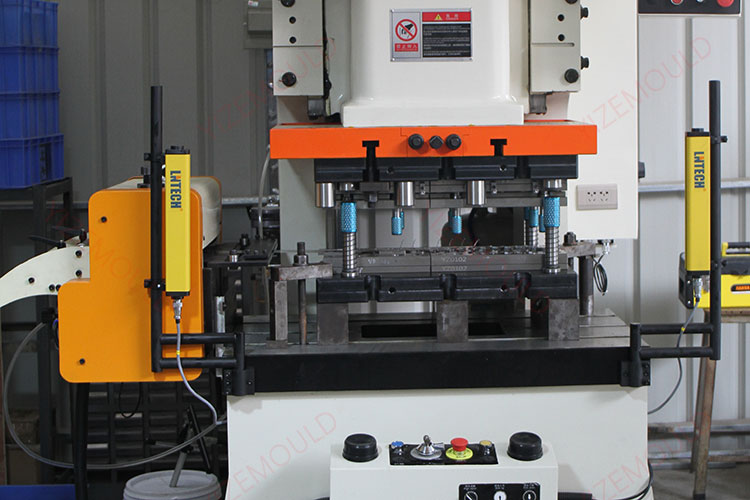

The selection of blanking dies materials is influenced by several factors, including the physical properties of the blanking material such as hardness, expected die life, production volume, and product requirements like performance and precision of the products. Blanking dies are critical tools in the metal forming industry, used for cutting out parts from sheets of metal in specific shapes. Choosing the right material for these dies is crucial for both performance and cost-efficiency. Here’s a detailed guide on how these factors should influence your choice:

- Consideration of Die Lifespan:

- While the lifespan of a die is a significant factor, it should not be the only criterion. The choice of steel or carbide should be made with an understanding of the balance between cost and the expected life of the die in production cycles.

- Type of Material Being Stamped:

- The material of the workpiece greatly influences die material selection. For softer materials like aluminum and copper, a less robust die material may suffice. However, harder materials like carbon steel and spring steel require dies made from materials with higher wear resistance and hardness to withstand the stresses of stamping.

- Production Volume:

- The batch size of the parts being produced plays a crucial role. For smaller runs, a less durable material may be economically more viable. For high-volume production, investing in a die made from high-grade carbide or advanced tool steels can reduce the need for frequent replacements.

- Physical Characteristics of the Stamped Part:

- The complexity of the part’s shape, size, thickness, and required dimensional tolerances demand careful consideration. More complex and precise shapes may require higher quality die materials to maintain accuracy and reduce wear over time.

- Cost Considerations:

- Evaluate the proportion of material costs in relation to the total cost of die manufacturing. If the die is complex and costly to machine, a higher performance die steel that might initially be more expensive can ultimately be cost-effective due to its longer service life and reduced maintenance needs.

- Die Hardness and Toughness Requirements:

- The cutting edges of blanking dies need to maintain high hardness and wear resistance, especially when dealing with tough materials. However, they must also possess sufficient toughness to prevent chipping or cracking under operational stresses.

Partner with Us for Your Carbide Die Needs

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

At our company, we specialize in the precision crafting of carbide dies, optimized for durability and performance. Our expertise extends to advanced manufacturing processes such as electrical discharge machining (EDM), CNC machining, grinding, wire EDM, and polishing. We are committed to providing high-quality, precision-engineered carbide parts tailored to meet the specific needs of your stamping operations. Whether you need assistance in selecting the right material for your blanking dies or require custom fabrication, our team is here to provide expert guidance and high-quality solutions. Please contact us to discuss how we can assist in enhancing your production capabilities with our specialized services.