Micro EDM Process: Precision Electric Discharge Machining Guide

Learn micro EDM machining principles, applications, and techniques. Guide to micro electric discharge machining for precision engineering.

Micro Electric Discharge Machining (EDM) is a sophisticated fabrication technique utilized in the precision engineering sector to machine conductive materials. This process diverges significantly from conventional machining methods by employing electrical rather than mechanical energy. Here, we delve into the fundamental principles that govern micro EDM and outline how it efficiently achieves high precision in machining.

Basic Principle of Micro EDM

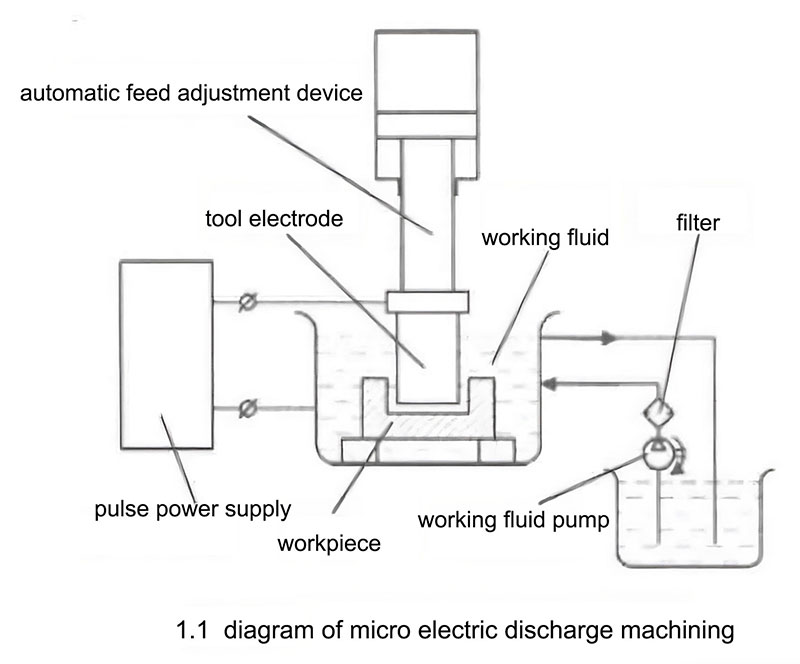

Micro EDM operates on the principle of removing material through the controlled use of electrical sparks that occur between a tool electrode and a workpiece, all contained within an insulating liquid medium. Figure 1.1 shows a schematic diagram of the basic equipment used in micro EDM. During the machining process, a pulsed power supply provides DC pulses, and an automatic feed control device maintains a small machining gap between the tool electrode and the workpiece. The metal is removed by the instantaneous high-temperature erosion caused by the pulsed sparks, resulting in discharge craters. Unlike traditional mechanical machining, which relies on mechanical energy for material removal, micro EDM relies on electrical energy. Additionally, because the tool electrode and the workpiece maintain a small gap without direct contact, there is no macroscopic cutting force, allowing for the machining of workpieces with higher hardness than the tool material. The key components and their functions in micro EDM are as follows:

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

Diagram of micro electric discharge machining

- Pulsed Power Supply:

- Generates direct current (DC) pulses that are essential for creating the electrical sparks needed for machining.

- Automatic Feed Control:

- Maintains an optimal small gap between the tool electrode and the workpiece, ensuring consistent spark generation and material removal.

- Electrode and Workpiece Interaction:

- The tool electrode and the workpiece do not physically touch; instead, a small gap is maintained where the sparks occur, allowing the tool to machine materials harder than itself without direct contact or macroscopic cutting forces.

Mechanics of Material Removal

The material removal process in micro EDM is facilitated through several steps:

- Formation of an Electric Field:

- A pulsed voltage creates an uneven electric field between the electrodes. When the field’s intensity reaches a critical value, it causes field emission, leading to the emission of high-speed electrons.

- Ionization and Breakdown:

- The emitted electrons collide with atoms in the working fluid, ionizing them and eventually causing a breakdown of the fluid, which forms a discharge channel.

- Heat Generation and Material Erosion:

- The rapid movement of ions and electrons within the channel generates significant heat, causing the material at the electrode surfaces to melt and vaporize, forming discharge craters.

- Removal of Erosion Products:

- The expansion of gas within the discharge channel exerts pressure that helps expel the molten and vaporized materials out of the discharge zone.

Control and Optimization in Micro EDM

In micro EDM, the control over pulse duration and interval is crucial. After each pulse discharge:

- Deionization of the Working Fluid:

- The working fluid needs time to return to its insulating state. Insufficient deionization can lead to undesirable stable arc discharges that can damage the machining process.

- Pulse Interval Time:

- Adequate time between pulses ensures that the fluid fully deionizes and clears out erosion products, preventing short circuits and ensuring the stability of subsequent discharges.

Applications and Advantages

Micro EDM is extensively used in industries requiring high precision and the ability to machine extremely hard materials. Its applications span across sectors such as aerospace for machining cooling holes in turbine blades, the medical field for creating intricate implants, and the tool and die industry for detailed mold making.

Conclusion

Micro EDM stands out in the manufacturing world due to its ability to machine conductive materials of any hardness with precision and without direct contact. This process is integral for producing complex geometries that are challenging to achieve with traditional machining methods. The ongoing development in micro EDM technology continues to enhance its capabilities, making it a critical tool in the arsenal of modern manufacturing techniques.