Micro-Milling: Benefits, Challenges, and Applications

The size range of parts processed by micro-milling generally falls between 0.1 to 10 mm. Micro-milling uses end mills with diameters less than 1 mm or even smaller. Milling is […]

The size range of parts processed by micro-milling generally falls between 0.1 to 10 mm. Micro-milling uses end mills with diameters less than 1 mm or even smaller. Milling is one of the most flexible cutting methods, and micro-milling is capable of diversely machining small, three-dimensional complex-shaped components. It falls under the category of traditional machining, with a mechanism similar to conventional milling, where cutting tools remove material from the surface of a workpiece.

Micro-milling is a high-precision, high-efficiency machining method, excelling in machining precise complex parts with small dimensions. As products become increasingly miniaturized and precise, the difficulty of machining and the requirements for machining accuracy increase as well. Micro-milling is an important method in micro-precision machining. It features unique advantages that include accommodating diverse materials and achieving three-dimensional surface machining. This technique is widely applied in fields such as microelectronics, aerospace, biomedical engineering, and precision equipment manufacturing. The processing of micro, complex, high-strength, high-precision, and multi-scale structural parts sets higher demands for micro-milling technology, demonstrating marked differences from conventional milling.

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: lei.jiang@carbide-products.com,

Advantages of Micro-Milling

- Versatility in Material Processing:

Micro-milling is adept at handling diverse materials. By utilizing cutting tools tailored in hardness and strength, it efficiently processes everything from metals to advanced polymers, showcasing its adaptability. - Capability for Complex 3D Geometries:

The process is particularly valuable for producing intricate, three-dimensional shapes at a mesoscale. This capability is crucial for manufacturing detailed components that are both functional and precise. - High Precision:

Micro-milling employs sophisticated tools such as polycrystalline diamond (PCD) and single crystal diamond cutters, achieving remarkable precision and superior surface finishes, often finer than 100nm. - Cost-Effectiveness:

When compared to other micromanufacturing methods like photolithography or micro-electrical discharge machining, micro-milling stands out as more economical, especially in large-scale production scenarios.

Challenges of Micro-Milling

Despite its advantages, micro-milling faces several technical challenges:

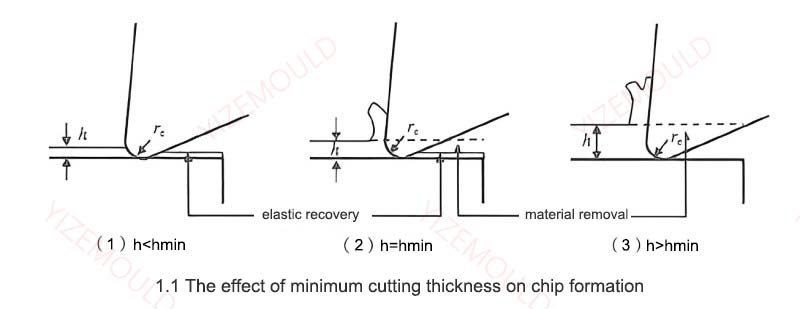

- Size Effects:

As the dimensions of the tool and cutting parameters near the scale of the cutting edge radius or the material’s grain size, the dynamics of cutting alter significantly. This shift can increase tool wear and lead to defects, impacting the overall machining quality. - Tool Manufacturing and Maintenance:

The complexity of producing and maintaining the sharpness of micro-milling cutters is a critical concern, affecting the integrity and quality of the machining process.

Applications of Micro-Milling

Micro-milling is integral in numerous high-precision industries, highlighting its versatility and importance:

- Aviation and Aerospace:

Essential for crafting detailed components in aircraft and spacecraft, where precision and component weight are paramount. - Communication Technology:

As electronic devices shrink while growing more sophisticated, micro-milling is vital for manufacturing the tiny, complex parts essential for modern smartphones and communication equipment. - Automotive Industry:

Micro-milling aids in the production of micro-scale components that enhance the performance and efficiency of automotive systems. - Optics and Photonics:

The technique is crucial for creating micro-lenses and other optical components, requiring the utmost precision that micro-milling provides.

Conclusion

Micro-milling is a cornerstone of precision engineering, enabling the production of small, intricate parts with high accuracy and cost-efficiency. As industries continue to pursue miniaturization in products like smartphones and medical devices, the significance of micro-milling is set to escalate. However, addressing the challenges related to size effects and tool maintenance remains essential for advancing this technology. For industries aiming to enhance their component manufacturing capabilities, micro-milling presents a compelling solution.