Micro Electrochemical Machining (ECM): Advantages and Challenges

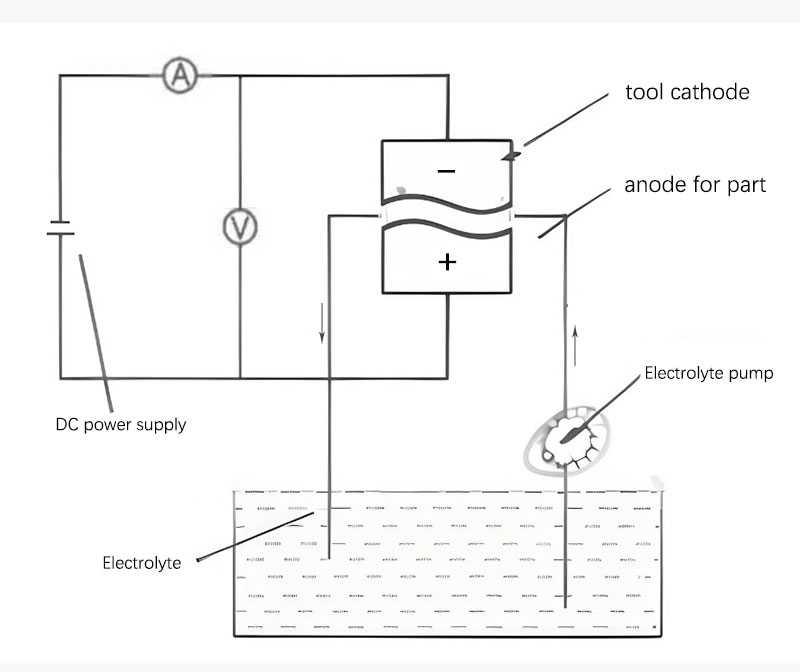

Micro Electrochemical Machining (ECM) stands out as a non-traditional machining process that leverages electrochemical anodic dissolution to shape workpieces precisely without direct contact between the tool and the material. This […]

Micro Electrochemical Machining (ECM) stands out as a non-traditional machining process that leverages electrochemical anodic dissolution to shape workpieces precisely without direct contact between the tool and the material. This technique is particularly advantageous for processing conductive materials of any hardness and complexity.

Advantages of Micro ECM

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

Micro electrochemical machining principle diagram

- Versatile Material Processing:

- Broad Range: Micro ECM can process various conductive materials, including hard-to-machine alloys and carbides, independent of their mechanical properties.

- High-Temperature Alloys and Stainless Steel: Particularly effective for materials that are otherwise challenging to machine using conventional methods.

- Non-Contact Technique:

- Reduced Tool Wear: The tool does not physically contact the workpiece, minimizing wear and extending tool life.

- Ideal for Delicate Parts: Suitable for machining thin-walled and easily deformable components without inducing mechanical stress or deformation.

- Superior Surface Quality:

- Smooth Finishes: Achieves surface roughness between 0.2-1.6 μm.

- No Heat or Mechanical Damage: The process avoids heat-affected zones, residual stresses, microcracks, burrs, or flash, ensuring a high-quality finish.

- Efficiency and Durability:

- High Cutting Rate: Micro ECM is capable of rapid machining, which is beneficial in high-volume production settings.

- Long-lasting Tools: The absence of physical wear and the non-depositional nature of the cathode reaction contribute to longer tool life.

Challenges and Limitations of Micro ECM

- Precision and Control:

- Comparative Accuracy: While highly effective, micro ECM may not always achieve the precision of processes like Electrical Discharge Machining (EDM), especially for intricate three-dimensional features.

- Control Issues: Machining small holes and narrow gaps can be challenging due to difficulties in controlling the electrolyte flow and maintaining stable process conditions.

- Environmental and Health Impact:

- Pollution Concerns: The by-products of electrolytic machining can be harmful to the environment and human health if not properly managed.

- Recycling and Handling: Special measures are required to manage and recycle electrolytic by-products to mitigate environmental impact.

- Equipment and Cost:

- Complex Setup: The equipment necessary for micro ECM is complex and requires significant space.

- High Initial Investment: The cost of setting up a micro ECM facility can be substantial, limiting its accessibility for smaller operations.

Applications of Micro ECM

Micro ECM is particularly suited for applications where the integrity of the surface finish is crucial and where traditional machining methods might compromise component quality. Its applications span various high-tech industries:

- Aerospace and Defense: Manufacturing parts with complex geometries and high-quality surface requirements.

- Automotive: Production of high-end components like diesel engine fuel injectors.

- Micro-Manufacturing: Fabrication of micro flat coils for sensors and tiny components for micro air vehicles.

Conclusion

Micro Electrochemical Machining offers significant advantages in terms of material versatility, surface quality, and component integrity, making it an invaluable process for industries requiring precise, high-quality machining of conductive materials. However, the challenges related to precision, environmental impact, and equipment cost need careful consideration to maximize the benefits and minimize the drawbacks of this advanced machining technology.