Position > > BLOG

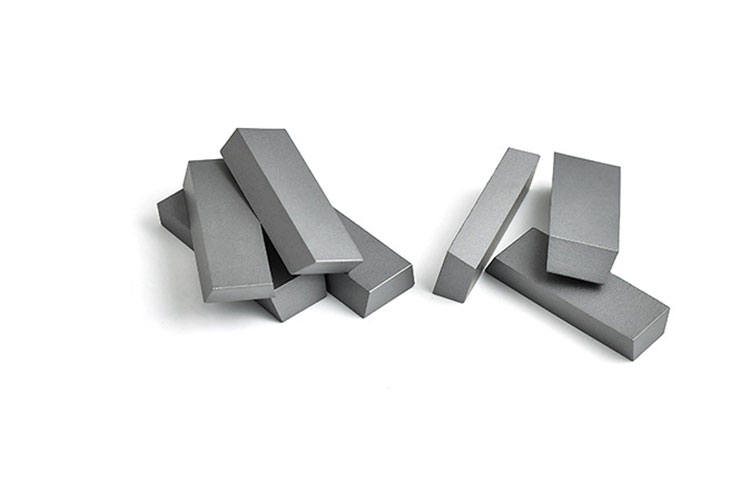

Sintered tungsten carbide components process

March 06, 2025

view: 838

I. Raw Material Preparation Mixing Ratio Mix tungsten carbide (WC) powders with metal binders such as cobalt (Co) according to the desired hardness, toughness, and application-specific requirements. The cobalt content […]

I. Raw Material Preparation

Mixing Ratio

- Mix tungsten carbide (WC) powders with metal binders such as cobalt (Co) according to the desired hardness, toughness, and application-specific requirements. The cobalt content typically ranges from 3% to 25%.

- Add trace amounts of tantalum (TaC), titanium (TiC), and niobium (NbC) to produce different types of alloy metals.

Ball Milling

- Utilize a wet ball milling process (using alcohol or acetone as the medium) for 24-48 hours to refine the powder particle size to 0.5-2.0 μm, ensuring uniform mixing.

- After ball milling, use centrifugal separation to remove the solvent, obtaining well-flowing mixed tungsten carbide powders.

Drying and Granulation

- Use spray drying to remove residual solvents and sieve out agglomerated particles, obtaining tungsten carbide raw material powders with uniform particle size distribution.

II. Forming Process

Pressing

- Press powders into tungsten carbide component green compacts under a pressure of 200-400 MPa, achieving a green compact density of 50%-60% of the theoretical density.

- Additives like paraffin and polyethylene glycol (PEG) can be added during forming to improve demolding performance; they are removed through pre-sintering.

Cold Isostatic Pressing (CIP)

- Use cold isostatic pressing on complex-shaped tungsten carbide components, applying pressure of 100-300 MPa to improve compact density and uniformity.

III. Sintering Process

The sintering process for tungsten carbide components is divided into four stages, with precise temperature and time control required:

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

| Stage | Temperature Range | Key Function | Duration |

|---|---|---|---|

| Debinding and Presintering | 400-800°C | Remove residual forming agents and reduce surface oxides | 1-2 hours |

| Solid-Phase Sintering | 800-1300°C | Particle diffusion densification, forming initial skeletal structure | 2-4 hours |

| Liquid-Phase Sintering | 1400-1600°C | Cobalt melts to form a liquid phase, filling pores for complete densification | 8-15 hours |

| Cooling | Cool to room temperature | Slow cooling or vacuum quenching to optimize material properties | Dependent on process |

IV. Innovative Sintering Technologies for Tungsten Carbide Components

Spark Plasma Sintering (SPS)

- Rapid heating at 100-200°C/min reduces sintering time to 10-30 minutes, with grain sizes controlled below 1 μm.

Nanocomposite Sintering

- Use high-entropy alloys (e.g., Al₀.5CoCrFeNiTi₀.5) as the bonding phase, resulting in triangular prismatic WC grains and hardness above 2500 HV.

V. Correlation Between Key Parameters and Performance

| Parameter | Typical Range | Effect on Performance |

|---|---|---|

| Cobalt Content | 6%-15% | Increasing cobalt content → Increased toughness, decreased wear resistance |

| Sintering Temperature | 1400-1550°C | Increasing temperature → Increased density, but risk of grain coarsening |

| Holding Time | 1-3 hours (liquid-phase stage) | Insufficient time → Pores remain; excessively long time → Grain growth |

Notes:

- The sintering process for tungsten carbide components requires parameter adjustments based on product type (tools, molds, wear-resistant parts) and optimization via orthogonal experiments.

- Strict control of hydrogen purity (≥99.995%) and vacuum levels (≤10⁻² Pa) is essential during production to avoid contamination.