Wire EDM Surface Finish – Electrical discharge machining Roughness Chart & Guide

Surface finish in electrical discharge machining (EDM): Oil cutting can achieve Ra 0.2 μm, water cutting can achieve Ra 0.4 μm, and EDM surface finish usually ranges between Ra 0.2-0.3μm, and a complete roughness chart to guide your machining decisions.

Wire EDM, also known as Electrical Discharge Machining (EDM), removes material using controlled electrical sparks. The process can achieve very fine surface finishes, often measured in Ra values ranging from roughing to ultra-fine finishing cuts. The surface finish achieved through electrical discharge machining (EDM) varies: oil cutting can achieve Ra 0.2μm, water cutting Ra 0.4μm, and EDM surface finish usually ranges between Ra 0.2-0.3μm, typically around Ra 0.6-0.8μm. In cases where parts cannot be polished, the high-quality surface finish produced by EDM or electrical discharge wire cutting becomes crucial.

Surface roughness and finish of the machined surface are key issues in electrical discharge machining. Roughness describes the surface profile and is typically indicated by the symbol Ra, measured in micrometers. It relates to the density and depth of surface textures. The value of Ra is significantly associated with surface finish quality. Surface finish measures the smoothness of a surface, reflecting light reflection characteristics. The smaller the surface finish value, the shinier the surface appears, and vice versa. Therefore, roughness and surface finish are two important indicators of the surface quality of carbide products, and controlling these values is a critical factor affecting part processing quality.

Low-price custom solutions. Our factory business includes designing, developing, and manufacturing powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts.

WhatsApp: +86 186 3895 1317 Email: [email protected]

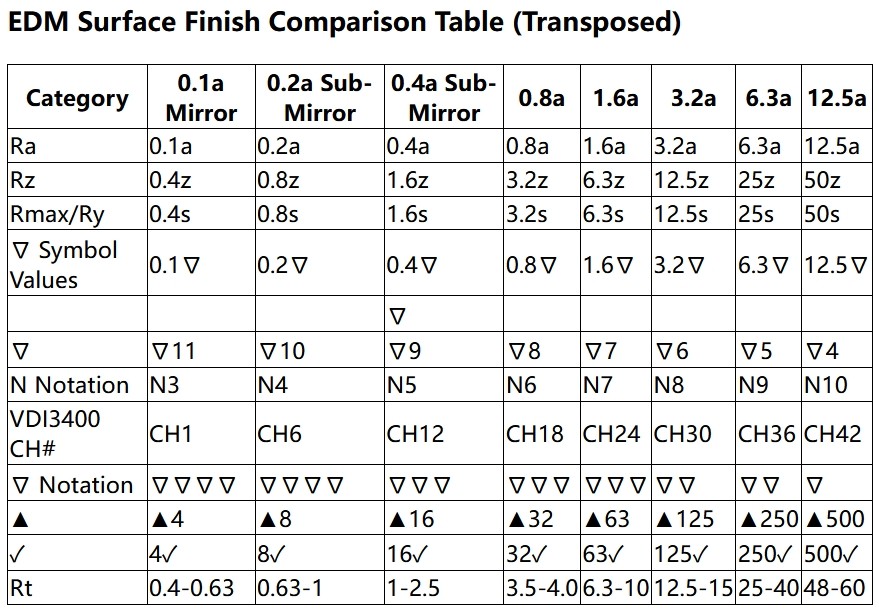

Wire edm (Electrical discharge machining) surface finish chart:

EDM Surface Finish Comparison Table (Transposed)

| Category | 0.1a Mirror | 0.2a Sub-Mirror | 0.4a Sub-Mirror | 0.8a | 1.6a | 3.2a | 6.3a | 12.5a |

|---|---|---|---|---|---|---|---|---|

| Ra | 0.1a | 0.2a | 0.4a | 0.8a | 1.6a | 3.2a | 6.3a | 12.5a |

| Rz | 0.4z | 0.8z | 1.6z | 3.2z | 6.3z | 12.5z | 25z | 50z |

| Rmax/Ry | 0.4s | 0.8s | 1.6s | 3.2s | 6.3s | 12.5s | 25s | 50s |

| ∇ Symbol Values | 0.1∇ | 0.2∇ | 0.4∇ | 0.8∇ | 1.6∇ | 3.2∇ | 6.3∇ | 12.5∇ |

| ∇ | ∇11 | ∇10 | ∇9 | ∇8 | ∇7 | ∇6 | ∇5 | ∇4 |

| N Notation | N3 | N4 | N5 | N6 | N7 | N8 | N9 | N10 |

| VDI3400 CH# | CH1 | CH6 | CH12 | CH18 | CH24 | CH30 | CH36 | CH42 |

| ∇ Notation | ∇∇∇∇ | ∇∇∇∇ | ∇∇∇ | ∇∇∇ | ∇∇∇ | ∇∇ | ∇∇ | ∇ |

| ▲ | ▲4 | ▲8 | ▲16 | ▲32 | ▲63 | ▲125 | ▲250 | ▲500 |

| ✓ | 4✓ | 8✓ | 16✓ | 32✓ | 63✓ | 125✓ | 250✓ | 500✓ |

| Rt | 0.4-0.63 | 0.63-1 | 1-2.5 | 3.5-4.0 | 6.3-10 | 12.5-15 | 25-40 | 48-60 |

SPI levels corresponding to Ra values and polishing tools

| SPI Level | Polishing Tool | Corresponding Ra |

| A0 optical requirements | #6 Diamond Grit 8000 | 0.012 |

| A1/#1 Mirror | #6 Diamond Grit 6000 | 0.025 |

| A2/#2 Mirror | #3 Diamond Grit 3000 | 0.05 |

| B1 Mirror | 600# Sandpaper | 0.08 |

| #3/B2 | 400# Sandpaper | 0.13 |

| C1 | 600# Oilstone | 0.4 |

| #4/C2 | 400# Oilstone | 0.8 |

| C3 | 320# Oilstone | 1.6 |

Electrical discharge wire cutting is a precision machining method in modern manufacturing, renowned for its high accuracy and versatility in processing various materials. However, the surface finish of the cut is often a key indicator of processing quality.

Key Factors Affecting Surface Finish:

- Optimization of Discharge Current: By optimizing discharge current and selecting lower current values, the discharge process can be effectively controlled to achieve a smoother cutting surface.

- Adjustment of Discharge Pulse Time: Adjusting discharge pulse time allows precise control over the energy output of EDM. Proper pulse timing can promote uniform melting and evaporation of material, thereby enhancing the surface finish of the cut.

- Control of Gap Between Molybdenum Wire and Workpiece: Appropriate gap control ensures continuous discharge while avoiding instability caused by excessive gaps, directly affecting surface finish.

- Appropriate Cutting Speed: The choice of cutting speed significantly impacts surface finish. Slower cutting speeds help improve smoothness by ensuring better control of the machining process.

- Inspection and Adjustment of Molybdenum Wire Wear: Regular inspection and replacement of severely worn wires are fundamental for maintaining surface finish quality.

- Maintenance of Worktable Flatness: Keeping the worktable flat can reduce vibration and deformation during the machining process, improving surface finish.

Impact of Surface Finish on Wire Cutting:

High-quality cutting surfaces not only enhance product appearance but also reduce the need for subsequent processing. Controlling the heat-affected zone and effectively relieving stress are vital to preventing cracks and deformation during processing.

How to Improve Wire Cutting Surface Finish:

- Choose Appropriate Cutting Conditions: Reasonable discharge and working fluid parameters are crucial to reducing surface roughness.

- Reduce Cutting Wire Diameter: The finer the cutting wire, the higher the surface finish.

- Utilize Advanced Molybdenum Wire Technology: Low-oxide composite molybdenum wire helps narrow the discharge gap and reduce surface roughness.

- Post-processing Measures: Techniques such as polishing, grinding, and electrochemical polishing can further enhance surface finish.