Understanding the Versatility and Production of Titanium Carbide (TiC)

Titanium carbide (TiC) stands out as a robust material primarily utilized in the creation of cemented carbides, which are indispensable in the manufacturing sector for cutting tools. Known for its […]

Titanium carbide (TiC) stands out as a robust material primarily utilized in the creation of cemented carbides, which are indispensable in the manufacturing sector for cutting tools. Known for its exceptional hardness and resistance to wear, TiC-based cemented carbide is perfect for not only precision machining of steel but is also highly effective in semi-precision machining, rough machining, and intermittent cutting of both steel and tough cast iron.

Manufacturing Process of TiC-Based Cemented Carbide

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

The process to produce TiC-based cemented carbide involves sophisticated techniques like liquid phase sintering. Initially, TiC powder is combined with nickel (Ni) or cobalt (Co) powders in a meticulously calculated ratio. This mixture is subjected to wet grinding in a ball mill, then dried, mixed with a lubricant, and compressed under immense pressures ranging from 150 MPa to 200 MPa. The resultant compact, often referred to as the green compact, undergoes a pre-sintering process at temperatures between 760 to 870°C, followed by a final vacuum sintering at a staggering 1250°C to 1900°C.

Key Factors Influencing the Performance of TiC-Based Alloys

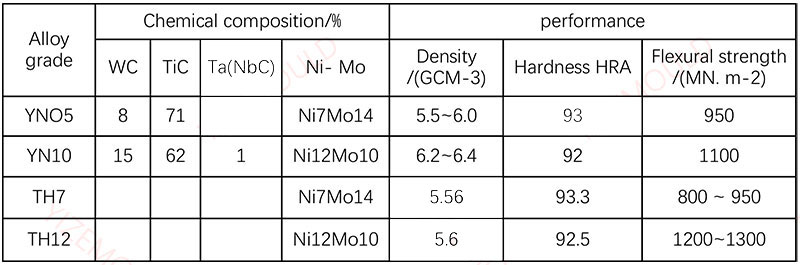

- Nickel Content: In TiC-Ni-Mo alloys, increasing the Ni content boosts the alloy’s flexural strength but reduces its hardness when the molybdenum (Mo) content is held constant.

- Molybdenum Content: Conversely, an increase in Mo content, with constant Ni levels, enhances the flexural strength due to Mo’s role in improving the binder phase’s wettability to TiC.

- Addition of Other Carbides: The inclusion of carbides like tantalum carbide (TaC), niobium carbide (NbC), and tungsten carbide (WC) generally acts as inhibitors of grain growth. While the addition of WC notably increases the strength due to improved binder phase wettability to TiC, it may slightly reduce the hardness because of the grain coarsening.

- Carbide Grain Size: Smaller TiC particles are preferable, as they contribute to superior strength of the alloy.

- Structural Defects: The presence of internal defects such as voids, Ni pools, and carbonitride aggregates can lead to brittle fracture, thus compromising the fracture strength. The strategic addition of molybdenum carbide (Mo2C) refines the structure and increases the liquid phase during sintering, which helps mitigate the formation of micropores and coarse carbides, thereby enhancing the overall strength.

Performance Insights

The performance of TiC-based carbide produced in China reflects significant advancements in material technology and production processes, ensuring that these materials meet the rigorous demands of modern industry. Each component and step in the manufacturing process is critical to the final properties of the tool, providing manufacturers with a competitive edge in high-stress applications.

By understanding these intricate details and the impact of various additives and processes, industries can better utilize titanium carbide to improve the efficiency and longevity of cutting tools, ultimately leading to more sustainable and cost-effective manufacturing practices.