Tungsten carbide bearings

The first manufacturing case of the Tungsten carbide bearings

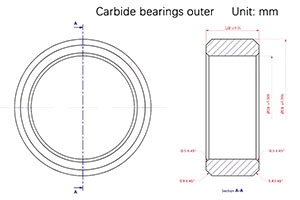

This tungsten carbide bearing has undergone the following manufacturing processes: Internal and external grinding-Carbide surface grinder-EDM-polishing;

- Info

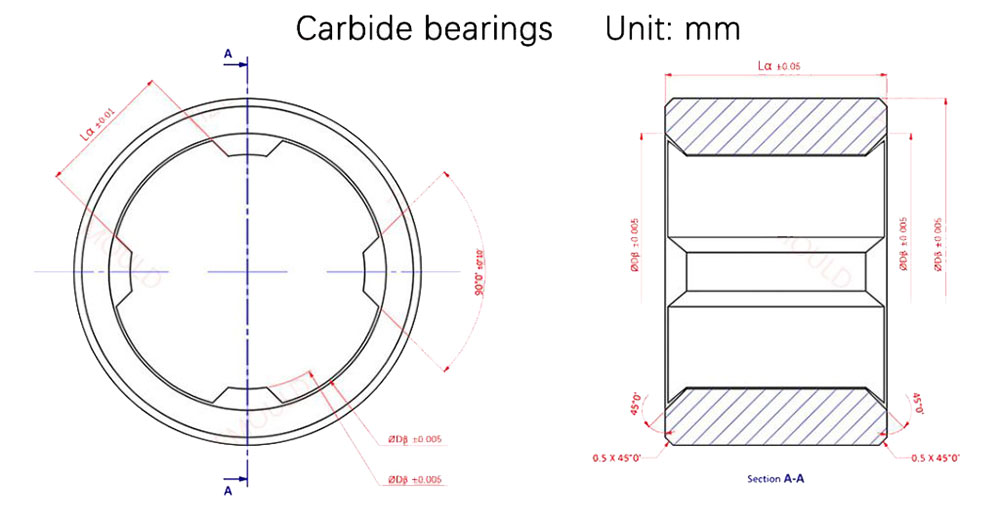

The first manufacturing case of the Tungsten carbide bearings

This tungsten carbide bearing has undergone the following manufacturing processes: Internal and external grinding-Carbide surface grinder-EDM-polishing;

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

Manufacturing difficulties

- Ensure the accuracy and angle tolerance

- cooperate with the bearing sleeve in the figure below using

What we can support?

The concentricity processing of tungsten carbide bearings can reach a tolerance of ±0.002mm, the vertical parallelism can reach ±0.002mm, the mirror polishing can reach RA0.01, and chamfering can be done at various angles (according to product drawings for evaluation).

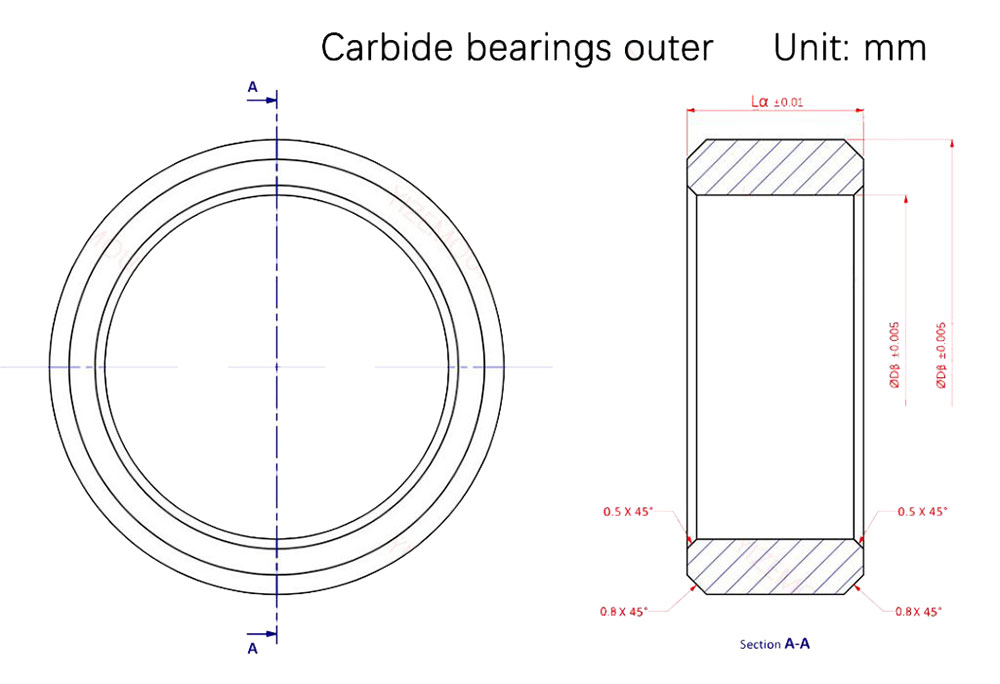

The picture above is a tungsten carbide bearing jacket, which has undergone the following manufacturing processes; inner and outer circles – flat grinding – CNC turning;

Processing challenges

the difficulty of this product is to ensure accuracy and angle tolerance, and it is used in conjunction with the inner ring of the bearing in the picture above.

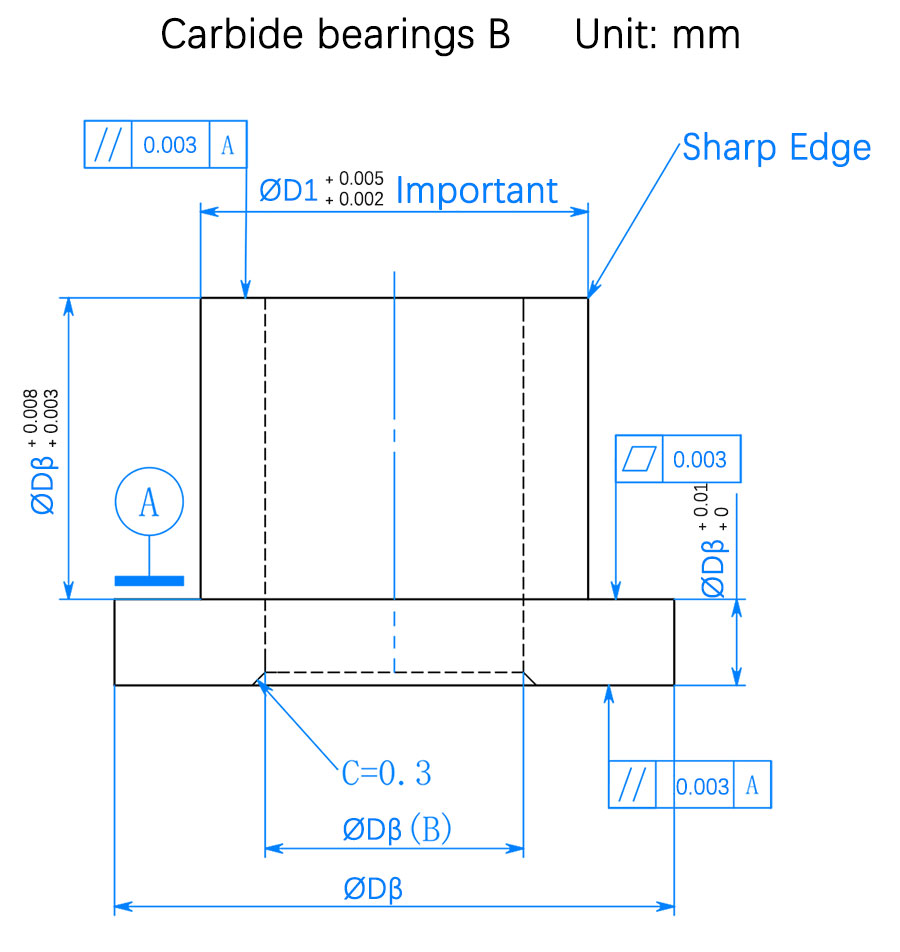

The second manufacturing case of the Tungsten carbide bearings

Manufacturing processes:

- CNC-inner grinding – Carbide surface grinder

- This tungsten carbide bearing has a different structure from the previous one, requiring high concentricity and parallelism.

What assistance do you require?

Get Mold has 15 years of experience in processing tungsten carbide parts. It can process various complex and high-precision tungsten carbide-bearing parts. The factory is located in Dongguan, Guangdong, China. For the processing service of the whole process of carbide bearings, please contact us!