Carbide wire drawing die

A first case study on mechanical components made of Carbide wire drawing die. The manufacturing processes; CNC – EDM – Carbide surface grinder. Processing challenges.

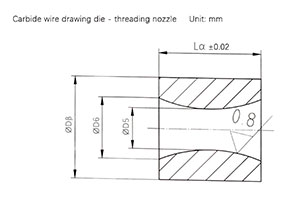

- Info

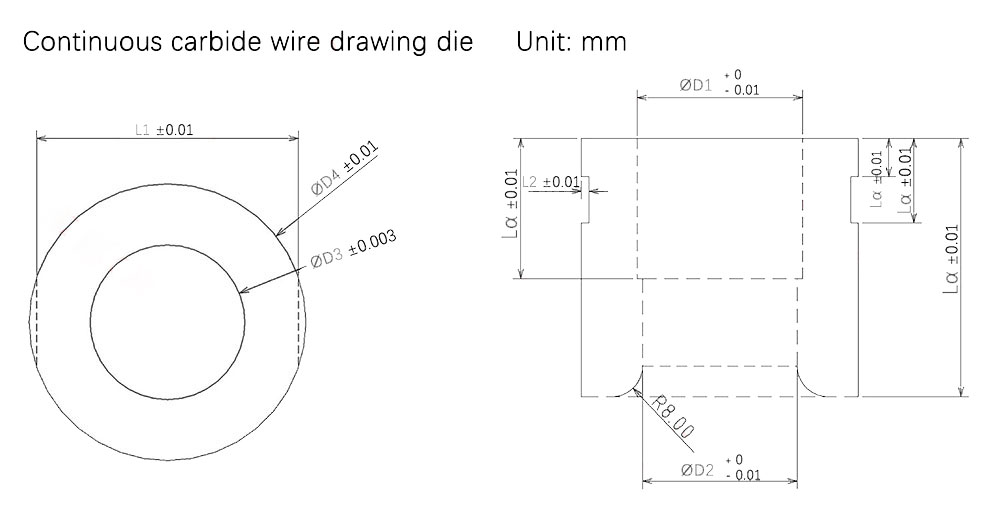

A first case study on mechanical components made of Carbide wire drawing die

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

The manufacturing processes; CNC – EDM – Carbide surface grinder.

Processing challenges.

- Ensure the tolerance of ±0.003mm in the position of D3.

- The concentricity processing of tungsten carbide wire drawing dies can achieve a tolerance of ±0.002mm.

- The vertical parallelism can reach ±0.002mm.

- The mirror polishing can reach RA0.01.

- The minimum hole processing can reach 0.06mm with a thickness of 0.6mm.

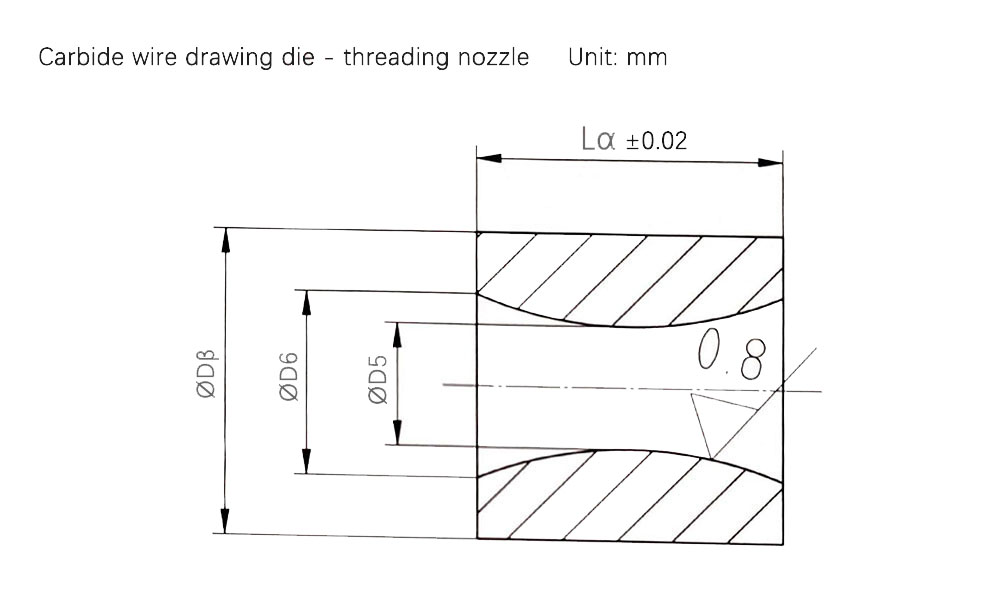

A second case study on mechanical components made of Carbide wire drawing die-threading nozzle of the metal wire

The manufacturing process: Carbide punch grinder – CNC – Carbide surface grinder.

Processing challenges:

Irregular-shaped holes can be made with a radian of more than 6mm directly. The specific hole diameter, hole depth and arc need to be evaluated according to the requirements of the drawing.

What can we do to support your needs?

Get Technology is a professional factory specializing in the processing of carbide wire drawing dies. Located in Dongguan, Guangdong, China, we have been in operation since 2007, and have built up extensive experience in a wide range of processing techniques, as well as a team of skilled manufacturing staff and advanced equipment. We offer customized processing of tungsten carbide parts in various shapes, starting from single pieces. Our commitment to quality and customer satisfaction has enabled us to build a strong reputation as a reliable provider of high-quality precision parts.