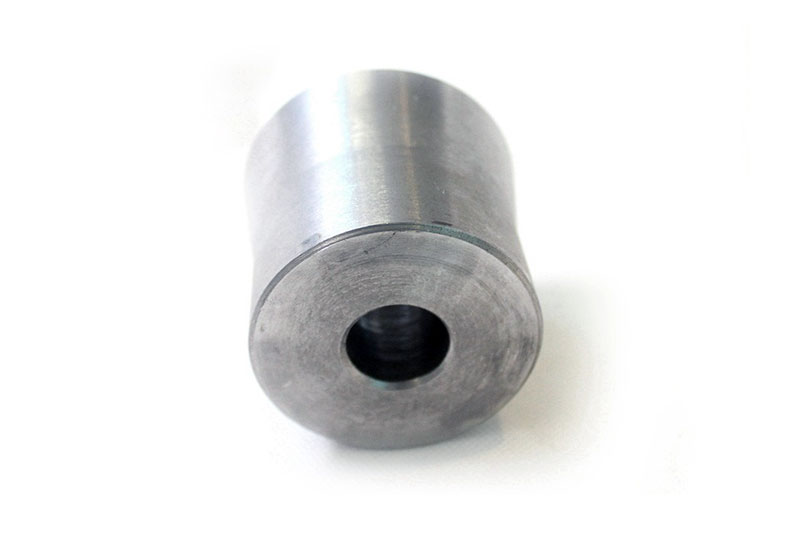

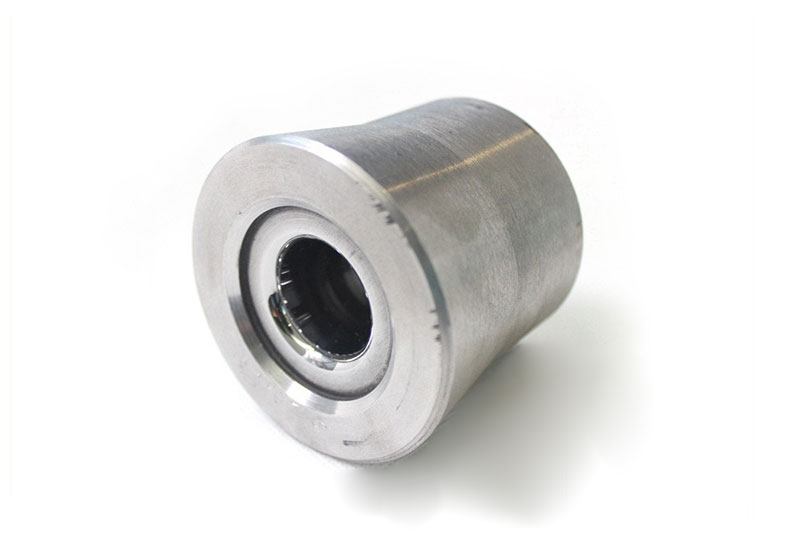

Cold heading mold customized supplier

Product Attributes Name: Carbide cold heading die, Grade: K20 , SKD51 , YG8, HSS Origin: China Main Metal Content: 99.9% Impurity Content: 0.1% Particle Size: 20-40 mesh Machining: Grinding, Wire […]

- Info

| Product Attributes | |

| Name: Carbide cold heading die, | Grade: K20 , SKD51 , YG8, HSS |

| Origin: China | Main Metal Content: 99.9% |

| Impurity Content: 0.1% | Particle Size: 20-40 mesh |

| Machining: Grinding, Wire Cutting | Customizable: Yes |

| Hardness: 81-95 HRA | Precision: 0.001 mm |

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

Materials for cold heading dies typically include high-speed steel, alloy steel, and tungsten carbide. Choosing the appropriate material based on factors like the die’s service life and production efficiency can enhance the performance and longevity of the die, ensuring the quality and efficiency of cold-headed parts production.

High-Speed Steel

High-speed steel is characterized by its high hardness, wear resistance, and heat resistance. Given the demands of high-speed stamping, cutting, and multiple heat treatments in cold heading die applications, high-speed steel is a common choice. Dies made from high-speed steel are durable and resistant to wear, high temperatures, and stamping, making them ideal for producing high-quality cold-headed parts.

Alloy Steel

Alloy steel dies are another common material for manufacturing cold-headed parts. This category includes a variety of steels such as Cr12MoV, 5CrMnMo, Cr12, CrWMn, and 9SiCr. Compared to high-speed steel, alloy steel dies offer superior wear resistance, heat tolerance, and toughness. They have a long service life and can manufacture larger cold-headed parts.

Tungsten carbide

Tungsten carbide, known for its high strength, hardness, and heat resistance, is widely used in manufacturing precision structural parts and large molds. It typically contains tungsten carbide particles like WC, TiC, TaC, NbC, and metal powders such as Ni, Co, Fe. tungsten carbide steel dies excel in wear and pressure resistance, making them suitable for producing complex cold-headed parts, such as those with intricate bottom holes and threads.