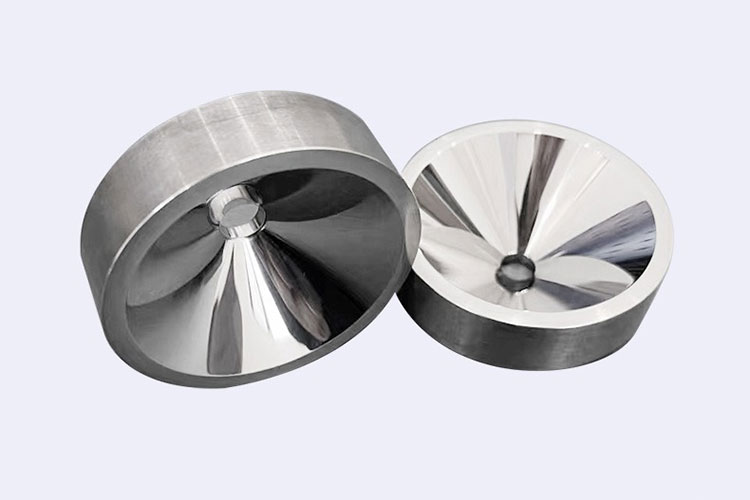

Conical concave tungsten carbide components

The machining of conical concave carbide components poses significant challenges due to their intricate shapes and precise dimensional requirements. As a material, carbide is characterized by its high hardness, superior […]

- Info

The machining of conical concave carbide components poses significant challenges due to their intricate shapes and precise dimensional requirements. As a material, carbide is characterized by its high hardness, superior wear resistance, and exceptional thermal stability, necessitating careful attention during the machining process.

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

Firstly, selecting the appropriate tool material and geometry is crucial. Typically, tools made of polycrystalline diamond (PCD) or cubic boron nitride (CBN), known for their high hardness and wear resistance, are employed to achieve superior cutting performance.

Secondly, it is imperative to strictly control cutting speed and feed rate during machining to prevent excessive tool wear or overheating. Adequate emphasis should also be placed on the cooling and lubrication of the workpiece to maintain the stability of both the workpiece and the tool, thereby ensuring high-quality machining outcomes.

Given the complex shape of the conical concave, it is necessary to appropriately adjust the relative positions of the tool and workpiece throughout the machining process to achieve precise dimensions and excellent surface quality.

The machining of conical concave carbide components is a technologically intensive process that demands specialized equipment, precise operation, and rigorous quality control. Generally, the precision machining of carbide components requires a coordinated multi-step process.

| Product Attributes | |

| Name: Conical concave carbide parts, | Grade: K20, K30, HSS |

| Origin: China | Main Metal Content: 99.9% |

| Impurity Content: 0.1% | Particle Size: 20-40 mesh |

| Machining: Grinding, Wire Cutting | Customizable: Yes |

| Hardness: 81-95 HRA | Precision: 0.005 mm |