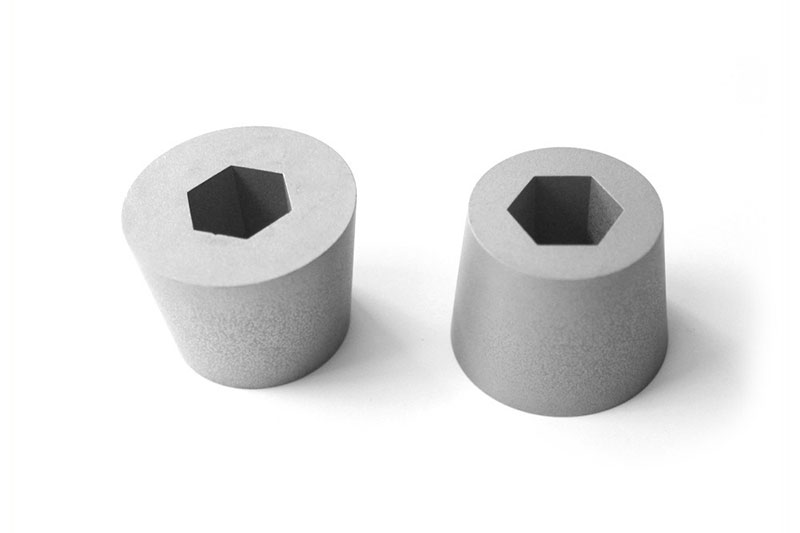

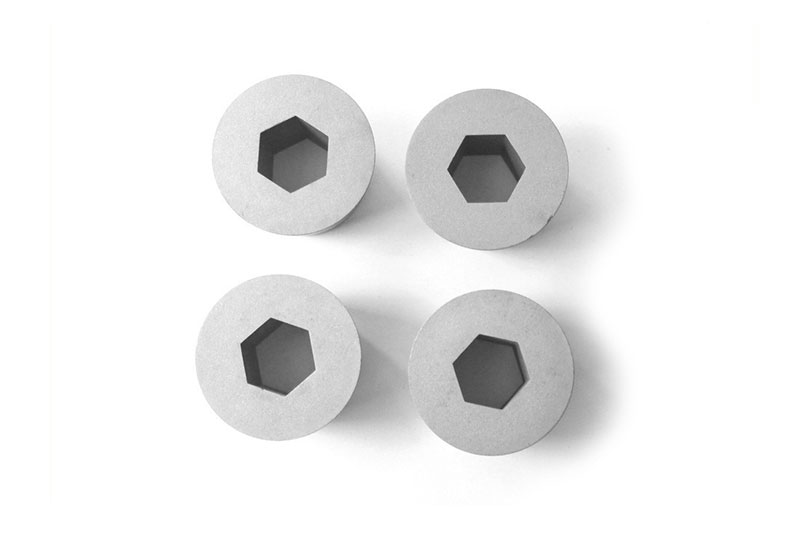

Precision carbide cold heading die factory

Product Attributes Name: Carbide cold heading die, Grade: K30 , SKD51 , YG8, HSS Origin: China Main Metal Content: 99.9% Impurity Content: 0.1% Particle Size: 20-40 mesh Machining: Grinding, Wire […]

- Info

| Product Attributes | |

| Name: Carbide cold heading die, | Grade: K30 , SKD51 , YG8, HSS |

| Origin: China | Main Metal Content: 99.9% |

| Impurity Content: 0.1% | Particle Size: 20-40 mesh |

| Machining: Grinding, Wire Cutting | Customizable: Yes |

| Hardness: 81-95 HRA | Precision: 0.001 mm |

In the cold heading process, the performance of die materials directly influences the durability of the dies and the quality of the products. Thermal fatigue resistance is one of the key properties of die materials. Due to the cyclic loading and high temperatures experienced during production, the dies are susceptible to thermal fatigue cracks and deformation. Therefore, it is crucial that the materials maintain structural stability and strength under these conditions. Materials such as high-speed steel and hard alloys, known for their excellent thermal stability and resistance to thermal fatigue, are preferred for creating dies that can withstand high temperatures and high stress.

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

Furthermore, cold heading die materials should also possess good toughness and impact resistance. During production, the dies endure continuous cold heading forces and impacts. If the material lacks sufficient toughness, it can undergo plastic deformation or even break. Therefore, materials capable of absorbing significant impact forces without damage are essential. Alloy tool steels and high-speed steels also perform well in this regard, making them suitable for producing large and complexly shaped cold heading dies.