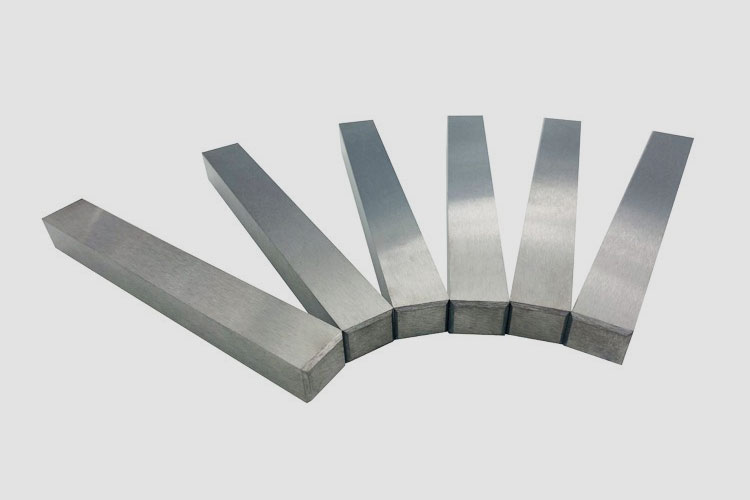

tungsten carbide wear parts long strips

Product Attributes Name:Customized wear parts long strips, Grade: K20, K30, W1, W2 Origin: China Main Metal Content: 99.9% Impurity Content: 0.1% Particle Size: 20-40 mesh Machining: Grinding, Wire EDM, Customizable: […]

- Info

| Product Attributes | |

| Name:Customized wear parts long strips, | Grade: K20, K30, W1, W2 |

| Origin: China | Main Metal Content: 99.9% |

| Impurity Content: 0.1% | Particle Size: 20-40 mesh |

| Machining: Grinding, Wire EDM, | Customizable: Yes |

| Hardness: 85-95 HRA | Precision: 0.005 mm |

Carbide wear parts long strips, composed of tungsten carbide (WC) and cobalt (Co) powders mixed in specific ratios, are manufactured through powder metallurgy processes including crushing, ball milling, pressing, and sintering. The main components are WC and Co, the proportions of which vary according to different application needs, enhancing their versatility. Due to their plate-like (or block-like) shape, these carbide wear parts long strips are also referred to as hard alloy blocks.

Our factory business: We design, develop and produce powder metallurgy moulds, carbide parts, powder injection moulds, stamping toolings and precision mould parts. Whatsapp:+8618638951317. Email: [email protected],

Carbide wear parts long strips possess excellent heat resistance, high hardness, outstanding wear resistance, high elastic modulus, and high compressive strength. They are chemically stable (resistant to acids, bases, and high-temperature oxidation), though they exhibit relatively low impact toughness. Other significant characteristics include a low coefficient of thermal expansion, and thermal conductivity and electrical conductivity similar to iron and its alloys.

In terms of applications, carbide wear parts long strips are extensively used in machining solid wood, medium-density fiberboard, gray cast iron, non-ferrous metals, chilled cast iron, quenched steel, printed circuit boards (PCB), and brake materials due to their high red hardness, good weldability, high hardness, and excellent wear resistance. When selecting carbide wear parts long strips, it is crucial to choose the appropriate material based on the specific materials and conditions to be processed, ensuring optimal performance.