-

-

What grinding wheel for carbide?

To grind tungsten carbide, it is preferable to use a diamond grinding wheel, followed by a CBN grinding wheel, and a green silicon carbide grinding wheel. Tungsten carbide is widely […]

More

carbide machining questions

Carbide machining questions and answers. Tungsten carbide machining services for various shapes, including holes, grooves, irregular shapes, arcs, etc.

-

-

Can you machine tungsten carbide with grinder?

Tungsten carbide can be machined using a grinding machine and is widely used. With its high hardness and wear resistance, tungsten carbide is extensively applied in industrial sectors. Machining tungsten […]

More

-

-

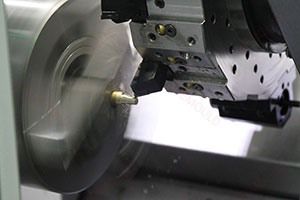

Tungsten Carbide Thread Machining

Cheap factory. The external threads of tungsten carbide are processed using CNC turning or precision grinding machines, while the internal threads of tungsten carbide are processed using CNC milling, EDM

More

-

-

What is the best way to machine carbide?

According to the product shape and requirements of tungsten carbide products, the optimal processing method should be determined. A professional process engineer’s arrangement and design of reasonable process sequences not […]

More

-

-

3 methods for how to cut carbide.

Common methods of cutting tungsten carbide include: Wire Electrical Discharge Machining (WEDM), diamond saw blades, and laser cutting. Depending on different conditions and requirements, different cutting methods are chosen. Carbide […]

More

-

-

Tungsten Carbide Machining Process Flow

Tungsten carbide parts machining includes smelting, sintering and forming, machining and forming, heat treatment, and surface treatment (polishing, PVD coating), as well as quality inspection. If the parts can be […]

More

-

-

How to machine tungsten carbide?

For different machining requirements of tungsten carbide, such as simple cutting, drilling, simple external shapes, complex shapes, flat or cylindrical surfaces, irregular non-through holes, blades, R-chamfering or curved profiles, different […]

More

-

-

How carbide inserts are made?

Carbide inserts are integral to modern machining and manufacturing industries, recognized for their exceptional hardness, wear resistance, and ability to withstand high temperatures. These features make them indispensable in settings […]

More

-

-

Cutting carbide with pcd tools

Carbide, characterized by its significant hardness and brittleness, is commonly employed in tool materials, molds, and various wear-resistant parts. Traditionally, carbide was shaped and refined primarily through grinding due to […]

More